outlined in the previous and following sections of this manual.

Do not overspeed the cutter by allowing more than 20 GPM to the cutter head. This

attachment requires 14-20 gallons of flow to cut efficiently.

When operating the cutter, set the skid steer throttle at a speed that will produce

the required flow. Refer to your skid steer manual or call your local skid steer dealer for

additional help, if necessary. Your skid steer dealer can measure the flow available on

your machine and recommend a throttle setting that is compatible with this attachment.

To begin with, learn what the cutter head looks like in a level cutting position when

you are seated in the skid steer. Knowing what a level cutter head looks like will help you

avoid damage to the cutting blades by cutting too close to the ground surface.

Rotate the boom 90

°

to the right and learn what the level position looks like when

cutting off to the side of the skid steer. Rollout the skid steer's tilt cylinder and notice how

it affects the cutter head.

The correct ground speed for cutting with this attachment can be monitored by

sound and feel and depends on the material density. If the skid steer engine is bogging

down or if the cutter speed is turning too slow because of too much load, the ground

speed should be decreased.

Listen and feel for any strange vibration when working the cutter. A bad vibration

felt when cutting could indicate a damaged cutting blade, or material trying to be cut at

too fast a pace. Slow down the skid steers ground speed to see if vibration stops. If it does

not, stop the cutter, turn off the skid steer engine and investigate cause of vibration.

Refer to the Troubleshooting section in this manual for further instructions.

Always be aware of your surroundings. When the cutter is swung 90

°

, the operator

has a much larger path to lf the cutter creates a vibration when ramping up speed, turn

the cutter attachment to the off position and investigate cause. Refer today

Troubleshooting section in this manual.

Never operate the cutter when bystanders are within 300' of your work areas. Flying

debris could result in Death or Serious Injury. Keep aware of. While watching the cutter,

also pay attention to what obstacles or terrain are in front of the cutter boom and prime

mover. Maintain a safe speed while cutting.

Cutting brush and tree branches with the cutter in an elevated position could result

in Death or Serious Injury if the skid steer becomes unstable. Never raise the cutter more

a few feet off the ground when working on slopes or uneven terrain.

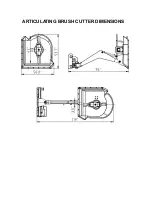

Adjusting Cutter Height & Level

Use the skid steer loader lift to adjust the elevation of the cutter. The fore & aft

leveling can be accomplished by using a combination of the tool cylinder mounted on the

boom and the skid steer's attachment tilt cylinders.

When the cutter is at the 0

°

position (straight in front of skid steer) the tool

cylinder on the boom can be moved to level the deck.

When the cutter is at the 90

°

position, it can be leveled by using the tool cylinder