16

GETTING TO KNOW YOUR WELDER….cont

Ref. No.

Description

Ref. No.

Description

A.

Shroud

E.

Swan Neck

B.

MIG Contact Tip

F.

Torch Handle

C.

Tip Adaptor

G.

Trigger Switch

D.

Gas Diffuser

Ref.

Description

Ref.

Description

1.

4 Roll Wire Feed Unit

15.

MIG / ARC Selector

2.

Interconnecting Harness

16.

2T / 4T Trigger Mode

3.

Inverter Welding Unit

17.

Manual / Synergic Selector

4.

Welding Torch

18.

Gas Purge On / Off

5.

Large Bottle Carrier

19.

Gas Type Selector

6.

Mains Lead

20.

Welding Wire Size Selector

7.

On / Off Switch

21.

MIG Inductance Control

8.

Bottle Chain

22.

ARC Force Adj in ARC / Crater Fill

Current Adj in MIG (4T

ONLY

)

9.

Fan Cooling Inlet

23.

Welding Current Adj in ARC / Crater

Fill Volts in MIG (4T

ONLY

)

10.

Output Current Display

24.

Welding Current Adj (Wire Feed

Speed)

11.

Output Volts Display

25.

Wire Feed ‘inching’ Button

12.

Supply Volts Indicator

26.

Welding Volts Adjustment

13.

Thermal Over Load / Fault Light

27.

Wire Spool Holder

14.

Output Volts Indicator

28.

Wire Feed Motor & Assy

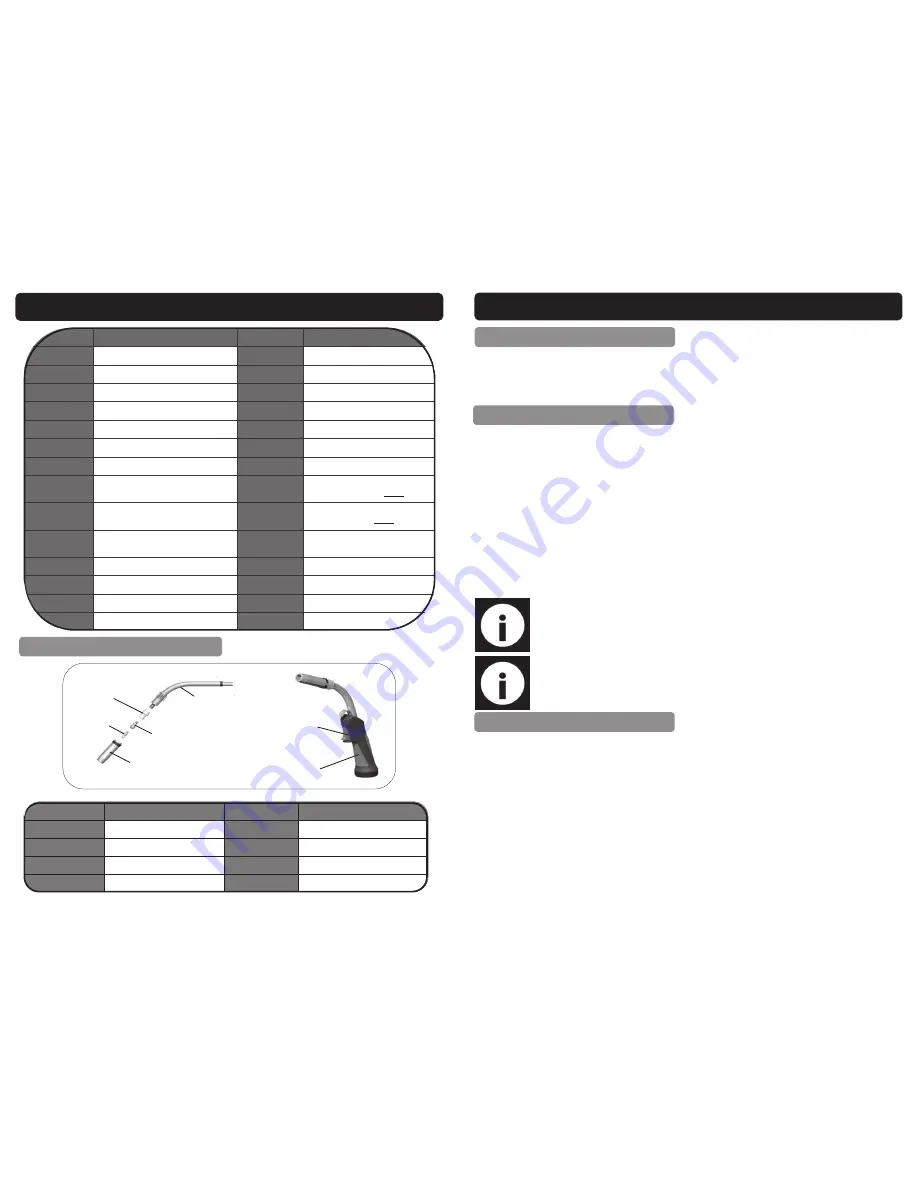

MIG Torch

A

G

F

F

G

A

B

C

D

E

21

OPERATING INSTRUCTIONS….cont

Clean the area to be welded, and the earthing point of all rust, paint and con-

taminants etc.

Place the earth clamp on to a cleaned area of the work piece.

PREPARATION FOR WELDING

Use the main On/Off switch on the rear of the welder to turn it on.

Select MIG symbol on the front panel.

Select MAN.

Select gas type; CO2 or MIX (Argon & CO2)

Select wire size; 0.8mm, 1.0mm or 1.2mm

Set the Weld Voltage, Wire Speed (Current Control), and the inductance by turn-

ing the appropriate controls.

Press the torch trigger and feed the wire out a little.

Cut the wire about 3mm from the MIG contact tip.

Turn the gas on .

Place a welding mask/shield over your face (not supplied).

WELDING—Manual MIG

Note: If the welder has a humming sound and a blob forms on the tip end, then you have insufficient wire

feed speed and it should be increased. If the welder has an erratic sound and the torch feels that the wire is

hitting against the work, then you have the wire feed speed to high and it should be reduced, when the wire

feed speed is correct you should get a steady crackling sound.

Note:

For future reference make a note of the voltage and wire speed set-

ting for the material that has been welded.

WELDING—Synergic MIG

Select SYN.

Select gas type; CO2 or MIX (Argon & CO2)

Select wire size; 0.8mm, 1.0mm or 1.2mm

Set the Weld Voltage, Wire Speed (Current Control), and the inductance by turn-

ing the appropriate controls.

Perform a weld test until you are happy with the welding condition selected.

There is no need to adjust the “Weld Voltage” knob again.

By turning the “Weld Current” knob the welding power and wire feed will auto-

matically adjust together. This enables the power range to be adjusted quickly

making it versatile for jobs requiring several power settings.

NOTE:- Adjustments CANNOT be made during welding.