Not for

Reproduction

20

Problem

Look for

Remedy

The auger does not stop within 5 seconds after

auger control lever is released.

The auger control cable is not adjusted correctly.

See

Adjusting the Auger Cable

.

The discharge chute or deflector in not adjusted

correctly.

Adjust the control linkage and pivot points.

See

Adjusting the Discharge Chute

or

Adjusting

the Deflector

.

The discharge chute or deflector does not work

(remote-manual).

The discharge chute or deflector needs lubrication. Lubricate the control linkage and pivot points.

See

Lubricating the Control Lever Linkage

.

The snowthrower does not stop when the traction

control is released.

The traction control cable is not adjusted correctly. See

Adjusting the Traction Control Cable

.

The kid shoes are not correctly adjusted.

Raise or lower the skid shoes. See

Adjusting the

Skid Shoe Height

.

The scraper bar does not clean hard surfaces.

Worn scraper bar.

Replace the scraper bar. See

Replacing the

Scraper Bar

.

The unit does not propel itself.

Incorrect adjustment of traction control cable.

See

Adjusting the Traction Control Cable

.

The auger control cable out of adjustment.

Adjust auger control cable. See

Adjusting the

Auger Cable

.

Broken shear pin or shear bolt.

Replace shear pin or bolt. See

Replacing the Shear

Pins or Shear Bolts

.

The discharge chute is clogged.

STOP THE ENGINE! Make sure that the auger and

impeller have stopped rotating. Use a clean-out

tool to remove the snow from the discharge chute.

DO NOT clear a clogged discharge chute with your

hands! See

Clearing a Clogged Discharge Chute

.

The unit does not discharge snow.

Unwanted debris is lodged in auger.

STOP THE ENGINE! Make sure that the auger and

impeller DO NOT rotate. Use a clean-out tool to

remove the foreign object. DO NOT clear a lodged

object with your hands! See

Clearing a Clogged

Discharge Chute

.

For all other issues, contact an authorized service dealer.

Specifications

Specification Chart

The spark ignition system on this snowthrower complies with Canadian standard ICES-002.

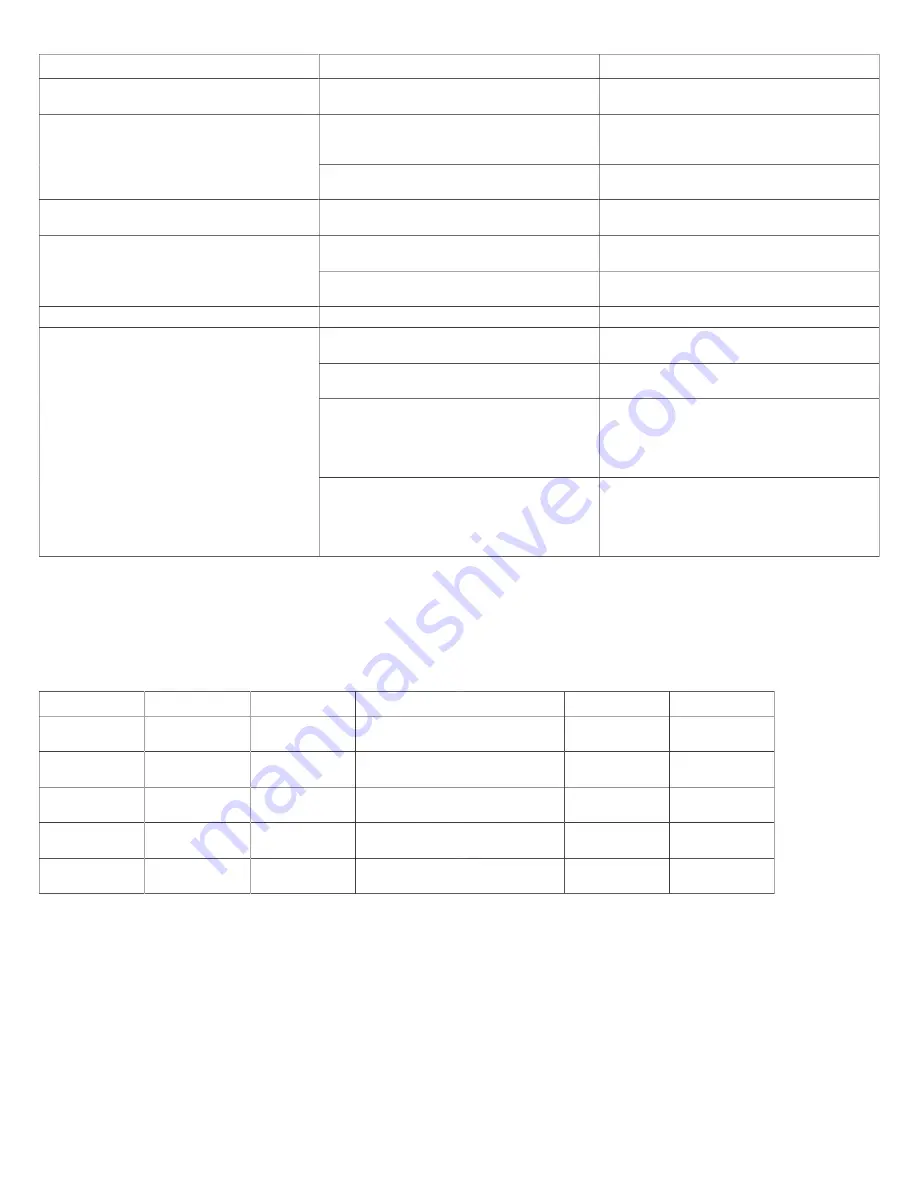

Item

Model 100000 Model 120000 Model 130000 Model 150000 Model 19J000 Model 250000

Armature air gap

.010 - .014 inch

(,25 - ,36 mm)

.010 - .014 inch

(,25 - ,36 mm)

.010 - .014 inch

(,25 - ,36 mm)

.010 - .014 inch

(,25 - ,36 mm)

.008 - .016 inch

(,2 - ,4 mm)

.008 - .016 inch

(,2 - ,4 mm)

Intake Valve

Clearance

.004 - .006 inch

(,10 - ,15 mm)

.004 - .006 inch

(,10 - ,15 mm)

.004 - .006 inch

(,10 - ,15 mm)

.004 - .006 inch

(,10 - ,15 mm)

.005 - .007 inch

(,13 - ,18 mm)

.005 - .007 inch

(,13 - ,18 mm)

Exhaust Valve

Clearance

.006 - .008 inch

(,15 - ,20 mm)

.009 - .011 inch

(,23 - ,28 mm)

.006 - .008 inch

(,15 - ,20 mm)

.009 - .011 inch

(,23 - ,28 mm)

.005 - .007 inch

(,13 - ,18 mm)

.005 - .007 inch

(,13 - ,18 mm)

Oil Capacity

18 - 20 oz

(,54 - ,59 L)

18 - 20 oz

(,54 - ,59 L)

18 - 20 oz

(,54 - ,59 L)

18 - 20 oz

(,54 - ,59 L)

36 - 38 oz

(1,0 - 1,1 L)

36 - 38 oz

(1,0 - 1,1 L)

Sparkplug gap

.030 inch

(,76 mm)

.030 inch

(,76 mm)

.030 inch

(,76 mm)

.030 inch

(,76 mm)

.030 inch

(,76 mm)

.030 inch

(,76 mm)

Engine power will decrease 3.5% for every 1,000 feet (300 meters) above sea level and 1% for every 10 degrees F (5.6 degrees C) above 77 Degrees F

(25 Degrees C). The engine will operate satisfactorily at an angle up to 15 degrees.

Power Ratings

The gross power rating for individual gasoline engine models is labeled in accordance with SAE (Society of Automotive

Engineers) code J1940 Small Engine Power & Torque Rating Procedure, and is rated in accordance with SAE J1995. Torque

values are derived at 2600 RPM for those engines with “rpm” called out on the label and 3060 RPM for all others; horsepower

values are derived at 3600 RPM. The gross power curves can be viewed at www.BRIGGSandSTRATTON.COM. Net power

values are taken with exhaust and air cleaner installed whereas gross power values are collected without these attachments.

Actual gross engine power will be higher than net engine power and is affected by, among other things, ambient operating

conditions and engine-to-engine variability. Given the wide array of products on which engines are placed, the gasoline engine

may not develop the rated gross power when used in a given piece of power equipment. This difference is due to a variety

of factors including, but not limited to, the variety of engine components (air cleaner, exhaust, charging, cooling, carburetor,