8

Installation

Adjusting Wheel Track (optional fixed axle)

The wheel track may require adjusting to match

the track of the tractor or to increase the stability

of the sprayer.

Use the maximum track on sloping terrain if

possible.

Lift the sprayer with a jack and support it with

stands under the drawbar and each side of the

frame behind the wheels.

On the standard axle loosen the four axle U-bolts

and the four set screws in the axle adjustment

sleeve. Slide the axle shaft on each side to the

required track and retighten the U-bolts and set

screws securely.

With standard tyres fitted the track may be set

between 1500 and 1580 mm, over the outside of

the tyres. Use an equal offset each side and do

not exceed the maximum track setting as this will

prevent proper engagement of the axle sections.

The track on the standard Glideflex axle is unable

to be adjusted.

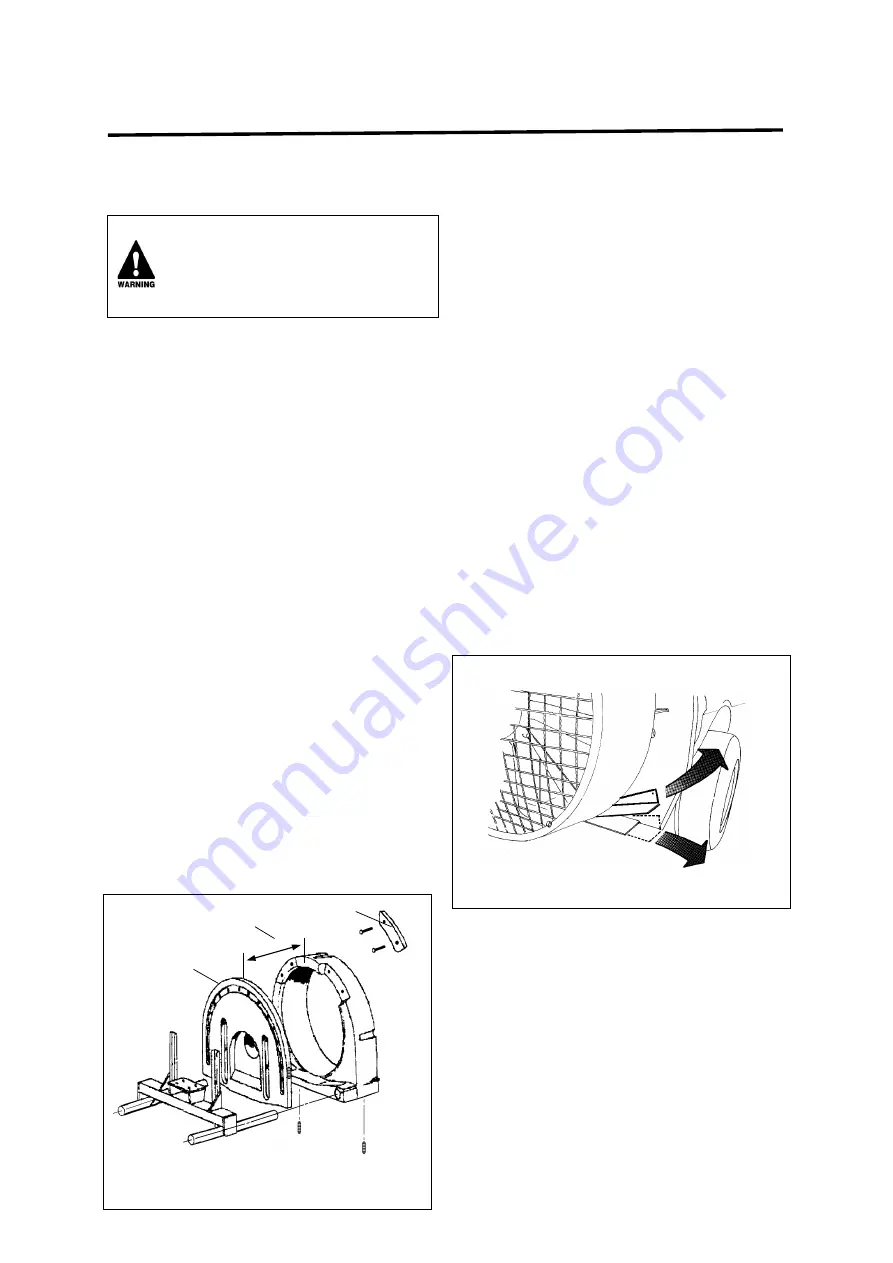

Adjusting the Fan

The Supaflo fan has four separate adjustments

which can be used to regulate the air flow to suit

particular applications.

1. Air Gap

The volume and velocity of the airflow

can be regulated by adjusting the gap between

the fan cowl and the mounting plate for the spray

nozzles. Moving the cowl in reduces the gap and

increases the air velocity, which is best suited to

vines and similar close plantings. Moving the cowl

out reduces the air velocity but increases the

volume, which is more suited to larger canopy

tree crops such as citrus fruits.

The cowl slides on two bars at its base and the air

gap is regulated by the threaded rod at the top.

To adjust the gap, use a 5mm Allen key to loosen

the two grub screws on the underside of the cowl

that lock onto the slide bars. Loosen the nuts on

the top threaded rod and move the cowl to the

desired position. The minimum gap is 100mm and

the maximum is 140mm. After adjusting, retighten

the nuts and grub screws.

2. Air Wedges

The air wedges are located on the

forward face of the fan cowling at the 10 o’clock

and 2 o’clock positions. Removing the wedges

increases the air flow to the upper area of the tree

canopy in crops such as apples and citrus fruits.

To remove the wedges, first remove the two 6mm

attaching bolts on each wedge.

3. Airflow Adjusters

An airflow adjuster is

located at the base of the fan on either side to

influence the direction of airflow. When angled

upwards the adjusters direct the airflow upwards

to suit free growing trees and taller crops. In the

horizontal position the adjusters direct the air

more laterally for spraying vines and small to

medium height crops.

The adjusters are positioned by removing the

outer attaching bolt, pivoting them to the required

location and reinstalling the outer bolt.

4. Blade Pitch

The pitch angle of the fan blades

can be adjusted to match the power output of the

tractor if required.

The larger the pitch angle the greater the volume

of air that will be displaced and the higher the

tractor power that will be required.

Normally when there is sufficient tractor power the

fan should be operated at full pitch and if a lower

volume of air is required the fan gearbox should

be set in the low speed position.

Do not attempt to adjust the track with

the tank filled or partly filled with liquid

or without the sprayer being properly

supported. Do not use the jockey wheel.

AIRFLOW ADJUSTER

Air Wedge

Air Gap

Nozzle

Mounting

Plate