3

Locating Tab & Hub Clamp screw

Operation

Pressure Adjustment

With the section switches turned Off and the

Master switch turned On maximum pressure

can be set by the Manual Pressure Regulating

Valve. A clockwise rotation increases pressure

and an anticlockwise rotation reduces

pressure. If the desired spraying pressure

cannot be obtained with the Manual Pressure

Regulating knob then holding up the toggle

switch on the control box will close the Electric

Pressure Regulating Valve and increase the

system pressure and vice versa.

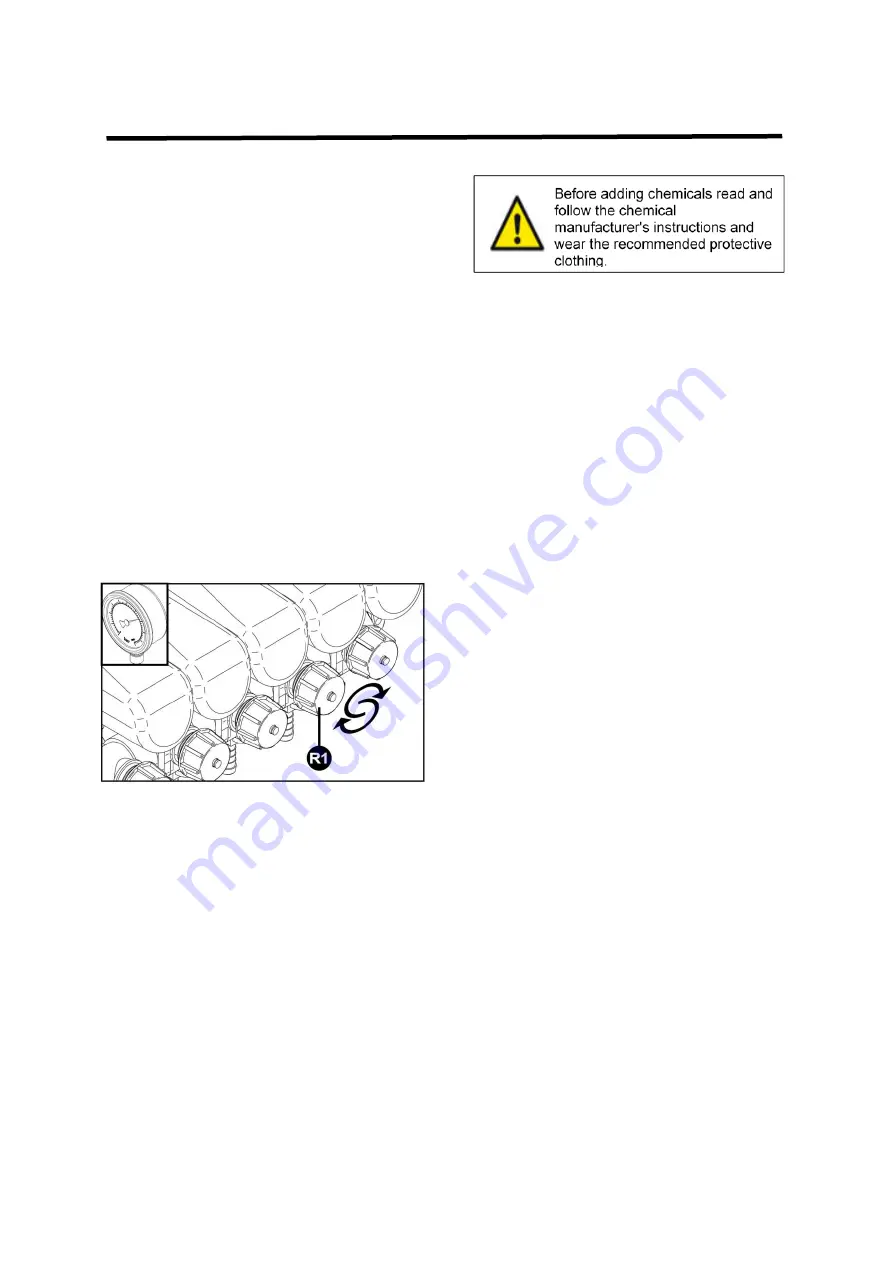

To adjust the compensation ports:

Start the sprayer and set the spray pressure

with the master On and all sections On.

Then turn off the first section and adjust the

compensation knob R1 until the pressure is

exactly the same as it was with all sections on.

Turn the section back on and off to check the

remains constant.

Turn all sections on again and repeat for the

remaining sections.

The sprayer is then adjusted correctly.

Adding Chemicals

Chemicals are added to the tank through the

top lid opening.

Take care to avoid the spillage of chemicals or

mixed solution. Wear gloves, eye protection

and the recommended protective clothing

whilst filling with chemicals. Wash your hands

after filling if they have come into contact with

concentrate or mixed solution.

Store unused chemicals and dispose of empty

chemical containers as recommended by the

chemical manufacturer or relevant authority.

Emptying the Sprayer

At the end of each day partly fill the tank with

water and run this through the pump, spray

lines and nozzles to purge them of chemicals.

Use a cleaning agent such as Silvan All Clear

tank cleaner.

Rinse the tank through the lid and empty with

the drain valve to remove powdered material.

Never leave chemicals in the tank that could

settle to the bottom and break into lumps that

may block the suction filter.

Dispose of unused chemical mix, rinse water

and containers as recommended by the

chemical

manufacturer

or

government

authority.