japa

315+

User manual

Translation

20

315+ 2.0 - 2020

5.

Maintenance and troubleshooting, all models

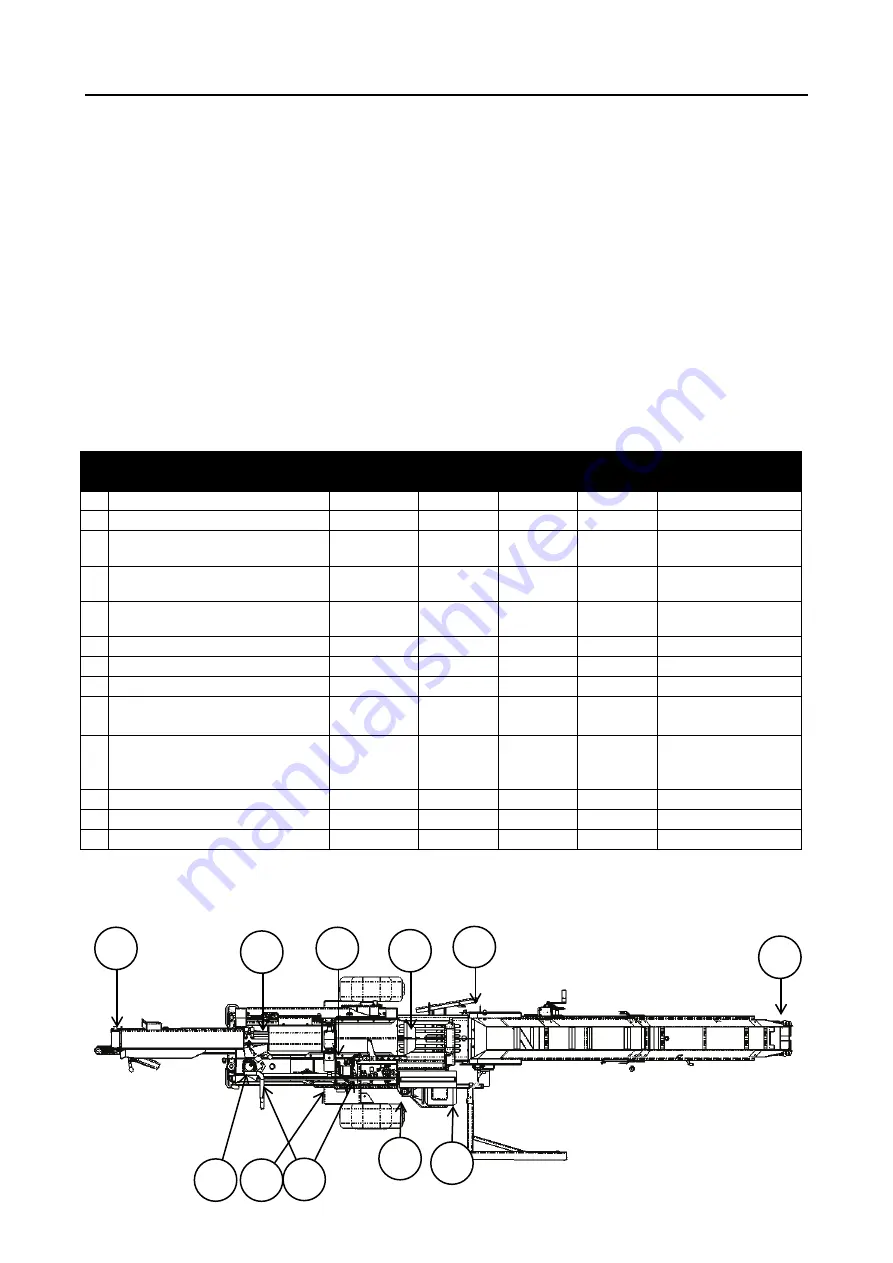

5.1 Maintenance table

A maintenance programme has been designed for the Japa firewood processor to ensure that its

service life is as long as possible. The owner is responsible for maintaining the device. Using the

machine carelessly and neglecting maintenance may void the guarantee. The maintenance tasks are

itemised as follows:

– 10 hr

Daily maintenance,

to be conducted before use.

– 200 hr

Monthly maintenance, at least once a year.

– 1,000 hr Annual maintenance, at least every other year.

When the machine is used for less than 200 hrs/year, the 200 hr maintenance is performed as the annual

maintenance and the 1,000 hr maintenance is performed every other year.

MAINTENANCE TARGET

TASK

INTERVAL

INTERVAL

INTERVAL

SUBSTANCE/ITEM

10 h

200 h

1000 h

A In-feed conveyor

Tighten

x

As necessary

B Splitting equipment

Clean

x

C Cutting blade

Check

Replace

x

As necessary

(96040/96043)

D Splitting knife

Check

Sharpen

x

As necessary

E

F

Out-feed conveyor, bearings

Out-feed conveyor, belt

Lubrication

Tighten

x

x

Ball bearing grease

G Saw lubrication oil

Fill

x

Saw chain oil (3 l)

H Electrical equipment

Clean

x

I Saw shaft, bearings

Grease

x

Ball bearing grease

J Transmission, oil (TR)

Check

x

SAE 80W-90

Replace

x

200 ml (0.2 l)

K Hydraulic oil

Check

x

Normal conditions

Oil filter

Replace

Replace

x

x

ISO 46 S / 30 l

94134/1 pc

Battery*

Check

x

Machine operation

Check

x

Safety equipment

Check

x

*)

accessory

G

A

C

B

F

E

J

D

H

I

K