4

2551 Magmeter

Important:

•

The directional arrow on the sensor body MUST be pointed DOWNSTREAM for best performance.

•

The FLOW arrow decal can be placed directly on the pipe to identify the direction of

fl

ow.

•

Use a cable gland or a liquid tight connector to seal the cable ports from water intrusion.

•

The yellow housing may be reversed to align the conduit ports as required.

•

If the Magmeter is installed on a vertical pipe, the conduit ports should be turned to point downward.

This will prevent condensation from being channeled into the enclosure.

•

Use plumber's tape or a suitable sealant on cable ports.

5. Hardware

Con

fi

guration

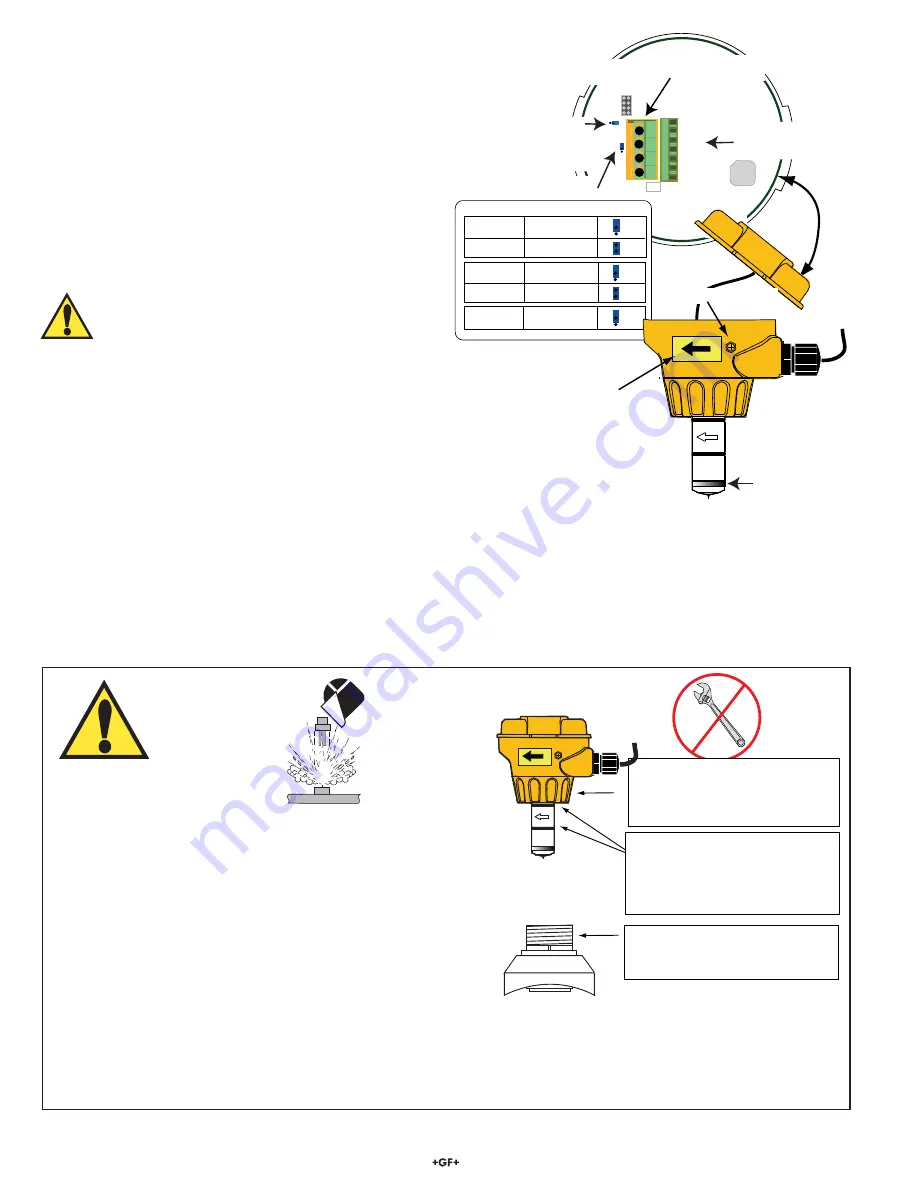

Whether using the 2551-XX-11 (frequency or digital S

3

L output)

or the 2551-XX-12 (with 4-20 mA output), the wiring terminals

located on the inside of the yellow cover are identical. All of the

connections from the Magmeter to external equipment (PLC,

Datalogger, Chart Recorder, Flow meter, etc.) are made at the

large 4-position terminal connector.

When the cover is removed the wiring from the sensor can be

seen connected to the smaller terminal block. These connections

should always remain connected to prevent inadvertent damage

or miswiring.

The terminals on the 2551 Magmeter are designed for conductors

from 16 AWG to 22 AWG.

WARNING!

If the second conduit port is used, carefully drill the opening.

(The plastic is too strong to be punched out.)

•

Secure the Magmeter in a vise to prevent damage or injury.

•

The plastic inside the port is very thin. Do not allow the drill

to penetrate too deeply and damage the Magmeter wiring.

1

2

3

4

JP2

White

Yellow

Red

Black

Brown

Blue

Not used

The factory connects

the sensor cable to the termin

inside the yellow cover.

This blue jumper selects

frequency output or

S

L serial data output

in the 3-2551-XX-11

(Not used on 4-20 mA models)

3

The user must connect output cables to

this 4-terminal block.

JP2 is for factory use only.

MAKE NO CONNECTIONS.

Use the yellow decal to mark

the direction of flow on the pipe

Set this blue jumper according to the pipe size.

External Earth Ground Terminal

Sensor Type

Pipe Size

Jumper Position

2551-P0/T0/V0/W0

½ in. to 2½ in.

DN15

to

DN65

2551-P0/T0/V0/W0

3 in. to 4 in.

DN80

to

DN100

2551-P1/T1/V1/W1

5 in. to 6 in.

DN125

to

DN150

2551-P1/T1/V1/W1 8

in.

DN200

2551-P2/T2/V2/W2

10 in. to 12 in.

DN250

to

DN300

Sensor grounding ring

3-9000.392-1

Liquid tight connec

(one supplied)

Flow

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN

THE SENSOR BEING EJECTED FROM THE PIPE!

•

DO NOT USE ANY TOOLS ON THE RETAINING CAP. HAND

TIGHTEN ONLY.

•

THE O-RINGS CAN BE LIGHTLY LUBRICATED TO FACILITATE

INSERTION INTO THE PIPE FITTING. DO NOT USE

PETROLEUM-BASED LUBRICANTS!

•

DO NOT USE THREAD SEALANT OR LUBRICANTS ON THE

RETAINING CAP OR ON THE PLASTIC FITTING THREADS.

•

IF LEAKING IS OBSERVED FROM THE RETAINING CAP, IT INDICATES DEFECTIVE OR WORN O-RINGS ON THE

SENSOR. DO NOT ATTEMPT TO CORRECT BY FURTHER TIGHTENING.

WARNING!

The O-rings can be lightly

lubricated to facilitate insertion

into the pipe fitting.

DO NOT USE petroleum-based

lubricants on O-rings!

DO NOT USE thread sealant

or lubricants on the fitting

threads.

Do not use any tools to

tighten the yellow retaining cap.

DO NOT USE thread sealant or

lubricants on retaining cap!

Flow