Model 3100 Series Flame Detector (11/04)

Page: 7

Instruction Manual

3.0 INSTALLATION

3.1 General Precautions

All wiring and installation must be done in accor-

dance with the NFPA 70 and 72 standards and must

comply with any codes specific to the application or

location. Contact the local authority having juris-

diction and the company safety engineer for infor-

mation on codes which may apply.

3.2 Housing and Conduit

3.2.1 Mounting the Housing

The housing is mounted by using the two

0.3” diameter holes located in ears on the

back of the housing. The two conduit holes

located on the side of the housing are not to

be used for mounting. The detector should

be mounted securely to a flat surface. The

mounting location must be strong enough to

support the detectors 3 lb. weight. Although

the detector is not vibration sensitive the de-

tector should not be exposed to excessive vi-

bration. "(The detector has been tested to

meet the vibration standard set in FM’s Ap-

proval Standard Class 3820, Sept. 1979.

(.022" displacement, 10 Hz to 30 Hz sweep

cycled at 2 cpm for 4 hours)"

3.2.2 Installing the Conduit and Wiring

Mount a “Seal Off” at the housing into the

3/4” NPT conduit(s) located on either side

of the housing. Connect the conduit to the

“Seal Off”. If one of the conduit openings is

not used insert a sealing plug into the unused

opening. Run the wires through the conduit,

“Seal Off”, and into the housing. The ends

of the wire should extend several inches (at

least 2” to 4”) beyond the front of the hous-

ing base.

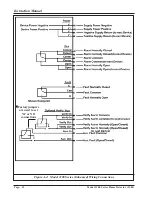

3.3 Connection (See Appendix C for information

regarding connection to various systems)

All connections are made on the back of the Model

3100 Flame Detector Module. Remove the housing

cover from the housing base. Loosen the two slot-

ted head captive screws located on the top of the

PC board. Lift the Detector Module out of the

housing base. Strip and connect the wires to the

connectors located on the back of the Detector

Module.

3.3.1 Power

Power for the 3100-01, -02, -03, -04 and -

05 flame detector is connected to the J5 con-

nector labeled “Power”. Connect the nega-

tive wire to PIN 1. Connect the positive (24

VDC) wire to PIN 4.

Power for the 3100-06 detector connected

to the J2 connector. Connect positive wire

at 4. Connect negative wire at pin 1. Pins 2

and 3 should be left open.

3.3.2 Fire Relay

The Fire Relay has two internal connection

points. Either or both may be used. The

Fire Relay connector, labeled “FIRE”, has

connection points for Normally Open, Nor-

mally Closed, and Common. The Normally

Open connections are labeled “Open”, the

Common contacts are labeled “Com”, and

the Normally Closed contacts are labeled

“Closed”.

3.3.3 Verify Relay

The Verify Relay has two internal connec-

tion points. Either or both may be used. The

Verify Relay connector is located between

the Power and Fire relay connectors. The

connection points are labeled “Verify In” and

“Verify Out”. The Verify relay is configured

for Normally Open (3100-02 and 3100-04),

or Normally Closed (3100-03 and 3100-05)

operation at the factory.

3.3.4 Fault Relay

The Fault Relay connector is labeled “Fault”.

The Normally Open connection is labeled

“O”, the Common connection is labeled

“Com”, and the Normally Closed connec-

tion is labeled “C”. The Fault Relay is a

normally energized relay. When the detec-

tor has no power the Normally Open contact

is closed and the Normally Closed contact is

open.