PLC Subroutines Manual

6FC5397-0FP40-0BA0, 08/2013

49

Table 3-20

Outputs

Name

Type

Description

Finish

BOOL

Part program selection finished

Error

BOOL

Part program selection error

Assigned global variables

SelPP_FinOm

BOOL

M239.6

Indicates that a part program has been selected

SelPP_ErrOm

BOOL

M239.7

Indicates that an error occurs when selecting a part program

Relevant PLC machine data

None

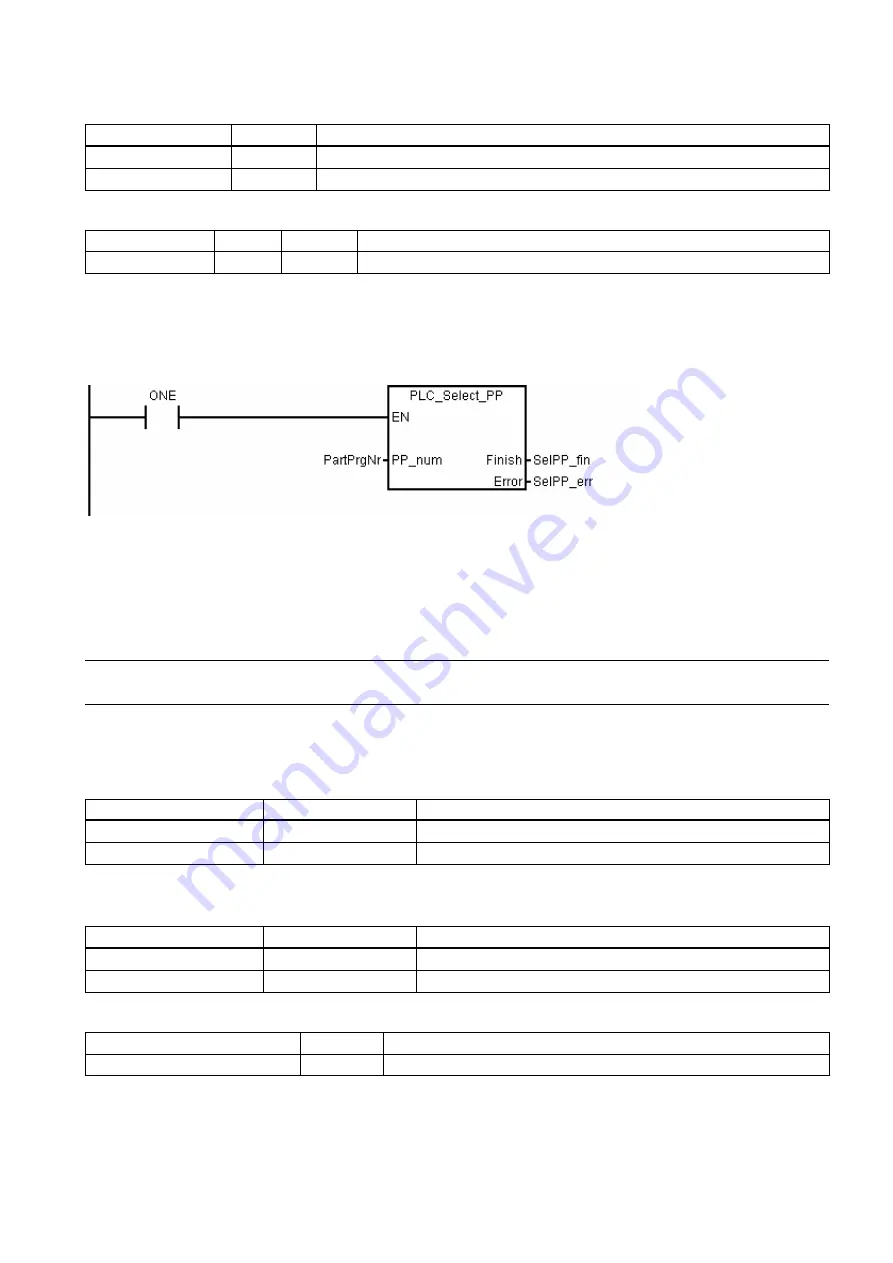

Example for calling subroutine 47

3.21

Subroutine 48 - ServPlan (service plan)

Purpose

To use subroutine 48, you must have created a service plan on the SINUMERIK 808D ADVANCED. When the pre-alarm

time arrives, the machine outputs a notification message. When the final alarm time arrives, the machine outputs an alarm

message.

Note

To perform a service plan on the PLC, you need to download DB9903(SP_INI) and DB9904(SP_ACT).

Local variable definition

Table 3-21

Inputs

Name

Type

Description

Deact0

BOOL

Freezing a service plan

AckMsg0

BOOL

Confirming the notification message of a service plan

Table 3-22

Outputs

Name

Type

Description

HintMsg0

BOOL

Notification message

Alarm0

BOOL

Alarm message

Assigned global variables

ServPlan_msg0

BOOL

Notification message of the first service plan

ServPlan_alm0

BOOL

Alarm message of the first service plan