9-2

Operator Panel OP3

Edition 11/99

After typing in the MPI address, you go to the operand field using the

→

ar-

row key. Hold down

SHIFT

and select the data type you wish to have dis-

played using the

↑

or

↓

arrow key. Pressing

ENTER

automatically sets the

corresponding data format in the format field.

Use the

→

key to go to the numeric field. Using the keypad, type in the num-

ber of the operand you wish to display or modify and press

ENTER

to con-

firm.

The cursor can be moved horizontally within the lines and value fields. A

total of 10 lines can be assigned. Confirm inputs one field at a time by

pressing

ENTER

. The values of the operands you select are displayed in the

value field in the specified format.

Single lines can be deleted by using the key combination

SHIFT

+

ESCAPE

.

When you have finished editing the operand list, the values on the PLC have

to be updated. This is not done immediately after an individual value has

been confirmed. Not until you press the

ENTER

key again after confirming

the final value are the new values transferred to the PLC. During updating, a

flashing asterisk * is displayed in the top right corner of the display. If the

asterisk does not flash, this means that a logical link has not been established

to the PLC. Inputs cannot be made while updating is in progress. Updating

can be canceled by pressing

ESCAPE

.

No inputs can be made while updating is in progress. You can abort updating

by pressing

ESCAPE

.

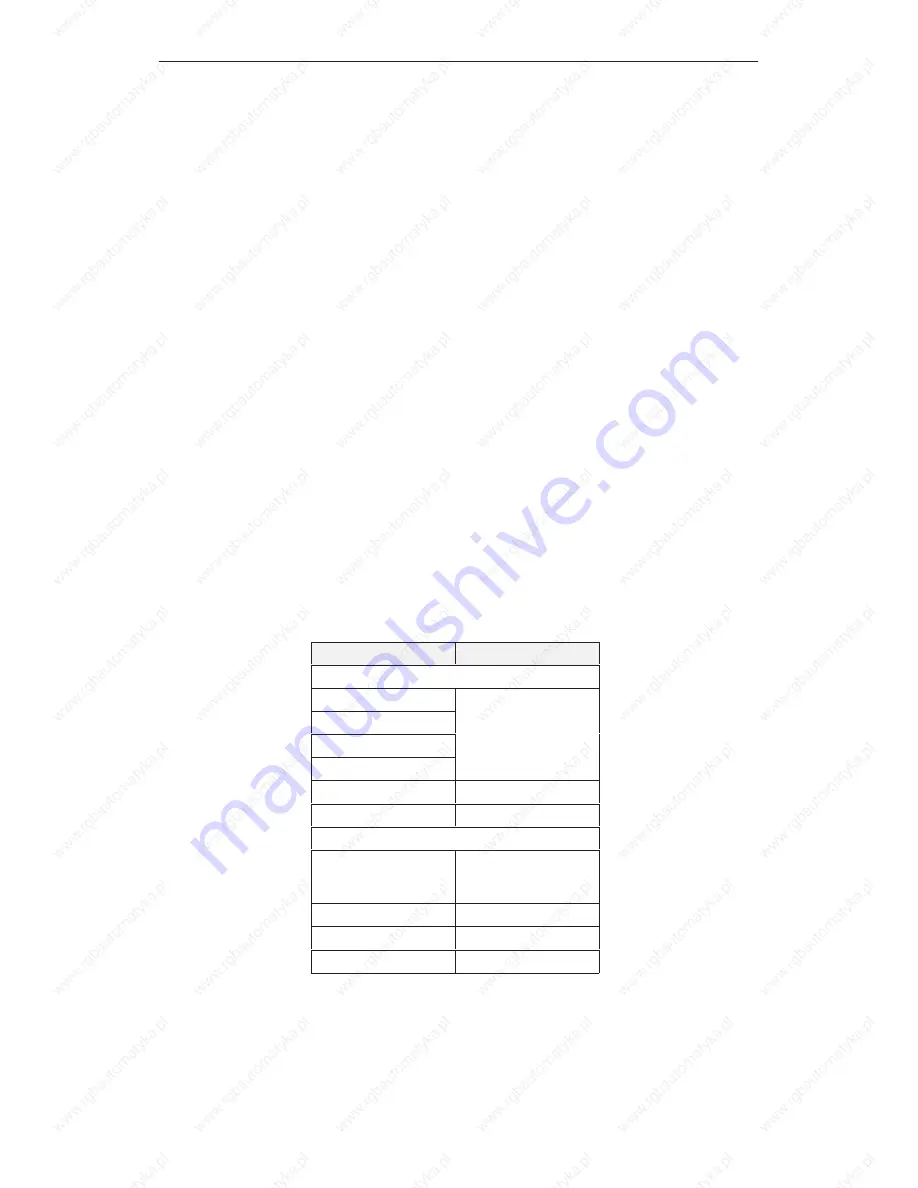

The table shows the data formats authorized for the SIMATIC S7-200 and

S7-300.

Address

Data Format

SIMATIC S7-200

V

WORD

I

O

F

T

TIMER

C

COUNTER

SIMATIC S7-300

DB, F

WORD

TIMER

COUNTER

I, PI, O, PQ

WORD

T

TIMER

C

COUNTER

Key functions

Authorized

data formats

STATUS VAR and FORCE VAR with the OP3

Summary of Contents for SIMATIC HMI OP3

Page 12: ...iv Operator Panel OP3 Edition 11 99 Contents ...

Page 13: ...INTRODUCTION 1 Product Description 2 Functionality Part I ...

Page 14: ...2 2 OperatorPanel OP3 Edition 11 99 ...

Page 18: ...1 4 OperatorPanel OP3 Edition 11 99 Product Description ...

Page 22: ...2 2 OperatorPanel OP3 Edition 11 99 ...

Page 34: ...4 6 OperatorPanel OP3 Edition 11 99 Using the OP3 with Its Standard Functions ...

Page 38: ...5 4 OperatorPanel OP3 Edition 11 99 Screens ...

Page 42: ...6 4 OperatorPanel OP3 Edition 11 99 Password Protection ...

Page 48: ...7 6 OperatorPanel OP3 Edition 11 99 Messages ...

Page 56: ...10 4 OperatorPanel OP3 Edition 11 99 System Settings on Standard Screens ...

Page 74: ...12 12 Operator Panel OP3 Edition 11 99 Communication ...

Page 75: ...INSTALLATION AND COMMISSIONING 13 Installation 14 Commissioning Part III ...

Page 76: ...12 2 OperatorPanel OP3 Edition 11 99 ...

Page 82: ...13 6 OperatorPanel OP3 Edition 11 99 Installation ...

Page 86: ...14 4 OperatorPanel OP3 Edition 11 99 Commissioning ...

Page 88: ...14 2 OperatorPanel OP3 Edition 11 99 ...

Page 96: ...P 2 OperatorPanel OP3 Edition 11 99 ...

Page 98: ...A 2 OperatorPanel OP3 Edition 11 99 Brief Description of Standard Screens ...

Page 112: ...D 4 OperatorPanel OP3 Edition 11 99 ESD Guidelines ...

Page 120: ...Glossary 4 OperatorPanel OP3 Edition 11 99 Glossary ...