10

PAD-4

Installation, Operation and Maintenance Manual

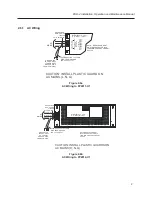

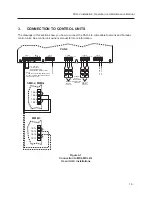

2.6.1.1 Wiring from FP2011-U1 and

FP2012-U1 to PAD-4-MB

FP2011-U1

TB10

+24V (Red)

(Blk)

Brownout

(Blue)

GND (Blk)

PSSI

PAD-4-MB

SEE FIGURE 2-6a

FOR WIRING

LN

G

A

V

ANT

ENTRETIEN

DESACTIVEZ

L

'UNITE

REMOVING

TERMINAL

BLOCK

PROTECTION

DISCONNECT

POWER

PRIOR

T

O

W

ARNING

Brownout PSSI GND +24V

170W

J3

300W

170W

J3

300W

Figure 2-7a

Wiring from FP2011-U1 Power Supply to PAD-4-MB

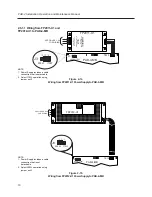

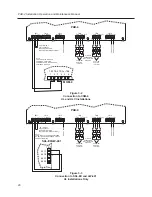

FP2012-U1

H

N

G

SEE FIGURE 2-6b

FOR WIRING

1 2 3 4

TB10

PAD-4-MB

Brownout PSSI GND +24V

300W

J3

300W

170W

J3

170W

Figure 2-7b

Wiring from FP2012-U1 Power Supply to PAD-4-MB

NOTE:

1. Power Supply includes a cable

connection that is not

detachable.

2. Select 300W operation using

jumper on J3.

NOTE:

1. Power Supply includes a cable

connection that is detachable.

2. Select 170W operation using

jumper on J3.