13

Installation

0

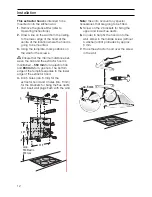

8.

Insert the other 4 screws with washers.

Before the 4 screws are tightened

down, align the extractor hood properly.

0

9.

Connect up the air outlet pipe.

10.

Connect the hood to the electricity

supply.

13.

Position the lower flue duct on the

extractor hood and screw the extractor

hood to the flue duct from below with

2 long screws.

To prevent scratching the upper

duct when pushing on the lower duct,

cover the edge of the lower duct with

the installation template or other

protective material.

Then screw the flue duct to the sides of

the fixing bracket with 2 short screws.

Before tightening the 2 screws,

align the flue duct.

14.

Re-insert the grease filter

(see operating instructions).

1.

2.

11. Stainless steel model:

❑

Remove the protective film from the

two flue ducts.

Avoid damage to the sensitive

surface.

12.

Screw the upper flue duct to the sides

of the fixing bracket with 2 short

screws.