CM2N4625E / 02.1999

Siemens Building Technologies

6/10

Landis & Staefa Division

All information and steps to properly prepare and mount the actuator are listed in the

Mounting Instruction guide M4626 delivered with the actuator. The shaft adapter as well

as all other individual parts are not pre-mounted as the actuator components are put

together differently depending the damper shaft length. Refer to "Mechanical design" in

this data sheet.

Select the mounting position so that you can easily access the cables as well as the

setting dials on the front of the actuator. Refer to "Dimensions".

In order to satisfy the requirements as per IP54, the following mounting conditions must

be fulfilled:

•

Mount the actuators only vertically (cabling see below) for air dampers with horizontal

shafts.

•

When the actuator is mounted directly on the damper shaft, the mounting angle my be

a maximum of +/- 45 °.

•

Use the ASK75.1 weather shield for mounting in any other position.

If you mount the actuator directly on the damper shaft, the mounting bracket must be

used. The insertion depth for the shaft into the housing must be sufficient and

guaranteed.

Information on minimum length and diameter for the damper shaft is listed in "Technical

data".

The actuator comes with a factory setting of + 2,5° which ensures a tight close-off for

the air dampers.

To ensure a tight close-off function for the dampers and the exact switching position for

switches A and B, the actuator can only be adjusted with a mounted shaft adapter and

position indicator in accordance with the mounting instructions.

If necessary, you can limit the rotational angle in increments of 5° for the entire span by

positioning the shaft adapter in the respective position.

The mounting sets which are used to change the rotational movement into a linear

stroke as described in "Type summary" are mounted separately.

All information necessary for commissioning is contained in the following:

•

This data sheet 4625

•

Mounting instructions M4626

•

Job diagram

Check to ensure that all permissible values as contained in "Technical data" are

observed.

•

Check for proper mounting and to ensure that all mechanical settings are in

accordance with the plant-specific requirements. Additionally, ensure that the

dampers are shut tight when in the closed position.

•

Fasten the actuator securely to avoid side load.

•

Check the rotation direction: The dampers must be able to be moved by pushing the

button "PUSH”.

•

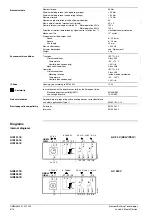

Check to ensure that the cables are connected in accordance with the plant wiring

diagram (see "Diagrams").

•

The operating voltage AC 24 V (SELV/PELV) or AC 230 V must be within the

tolerance values.

Mounting notes

Mounting instructions

Mounting position

Housing protection

Mounting bracket

Damper shafts

Actuator factory setting

Manual adjustment

Mechanical limitation of

the rotational angle

Using the mounting sets

Commissioning

notes

References

Environmental conditions

Mechanical check

Electrical check