62

••••

Data Communications Setup

2000585-001

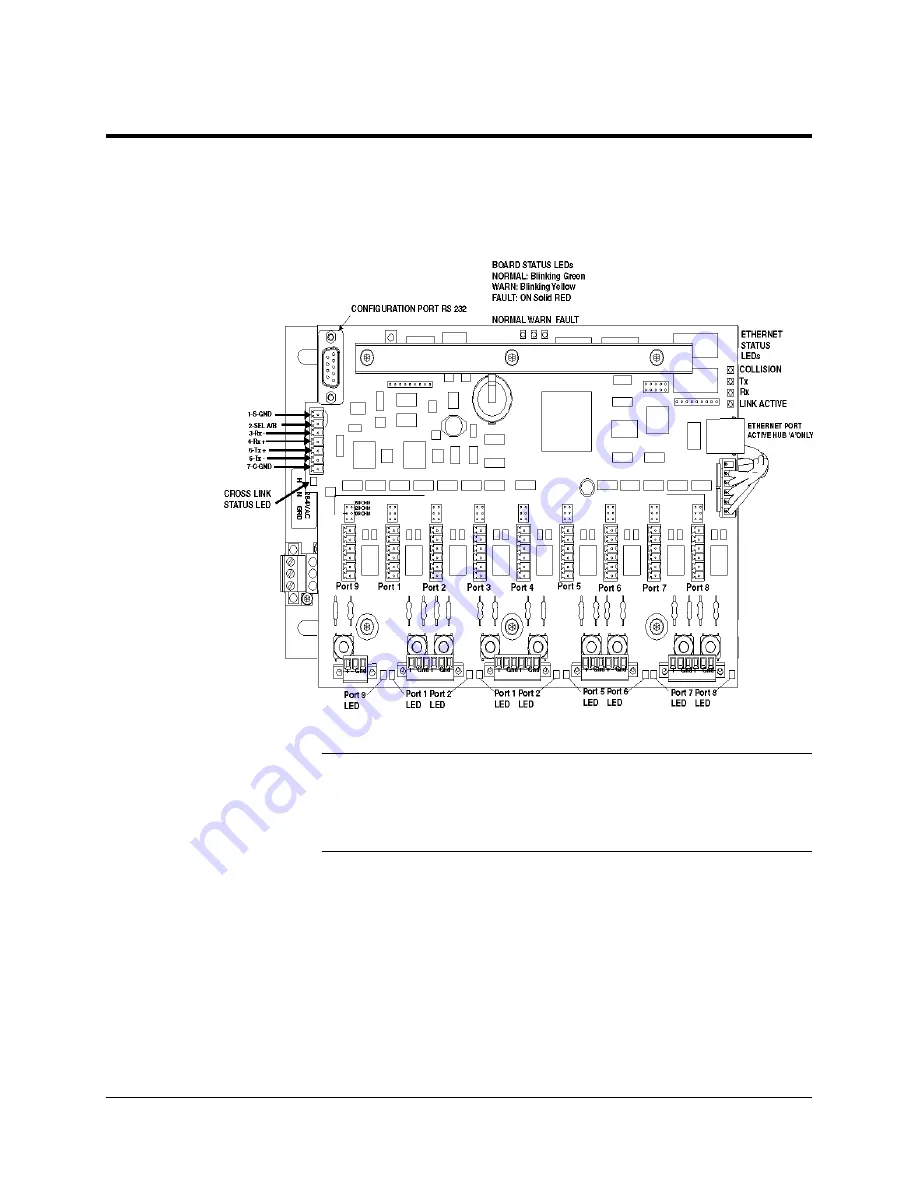

System Status LEDs

The Advance DataNET Hub Communication boards have status LEDs

for monitoring the DNH operation.

During the power-on self-test, all the LEDs will light briefly to indicate that

all LEDs and their driving electronics are functioning.

After a normal power-up and a successful self-test, the green (NORMAL)

system status LED will light. In the event of a self-test failure, the red

(FAULT) system status LED will light, and the yellow (WARN) system

status LED will flash an error code. The same indication (red LED on;

yellow LED blinking) is used to indicate duplicate IP addresses.

Description

Figure 3-1.

Status LEDs

Board Status LEDs

Startup LED Status