7

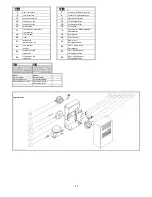

10. Maintenance.

Caution! Before embarking on any mainte-

nance work, switch current off to the enclo-

sure.

The cooling unit is the low maintenance

type so no filter change is required. The only

jobs that need doing are the internal compo-

nents with compressed air at a maximum pres-

sure of 4 bar (figure

F.34.1

) and which should

be checked regularly.

Job

Frequency

Check the external air heat

exchanger and clean if

necessary

Every 3

months

Check effectiveness of the

condensate discharge

Every 3

months

Check the fans for any

overheating or excessive

vibrations

Every 6

months

Any repairs that may need doing must only be

done by specialised and authorised personnel

and using original spare parts only.

11. Technical information.

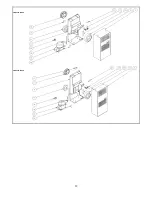

11.1 Operating principle.

The cooling unit for electric enclosures works

on the basis of a refrigeration circuit consisting

of four main components: compressor, evapo-

rator, condenser and expansion device (figure

F.36.0

). The circuit is hermetically sealed and

the refrigerant circulates inside

it. The refriger-

ant used is R134a, chlorine free and harmless

for the ozone layer. The unit is divided into two

hermetically separated sections where the am-

bient air and enclosure air do not come into

contact with one another and are treated sepa-

rately. The compressor (CP) compresses the

refrigerant and takes it to a high pressure and

high temperature. The compressor then pushes

the refrigerant through a heat exchanger coil,

called condenser (C), where it is cooled by am-

bient air thus passing from the gas to the liquid

state. At the liquid state it then passes through

the capillary (EXP) and as it is at a much lower

pressure, nebulizes at the outlet. It is then re-

ceived by the heat exchanger coil, called

evaporator (E), by means of which it absorbs

heat from the enclosure air and passes from a

liquid state to gas. The enclosure is cooled

down in this manner. The gas is then drawn

back into the compressor and the above de-

scribed cycle is repeated.

11.2 Safety devices.

The refrigeration circuit is fitted with a high

pressure safety switch P (figure

F.36.0

) set at

maximum cooling unit working pressure. If the

threshold is exceeded, the pressure switch

stops the compressor working. It is the auto-

matically resettable type. The fans and com-

pressor have a thermal cut-out switch inside

that stops them in the case of anomalous over

temperatures.

11.3 Disposal.

Caution! The cooling unit contains R134a re-

frigerant and small quantities of lubricating

oil

. These substances pollute and must not be

dumped. Replacement, repairs and final dis-

posal must be seen to by experts.

NOTE

Keep the documentation in a dry place.

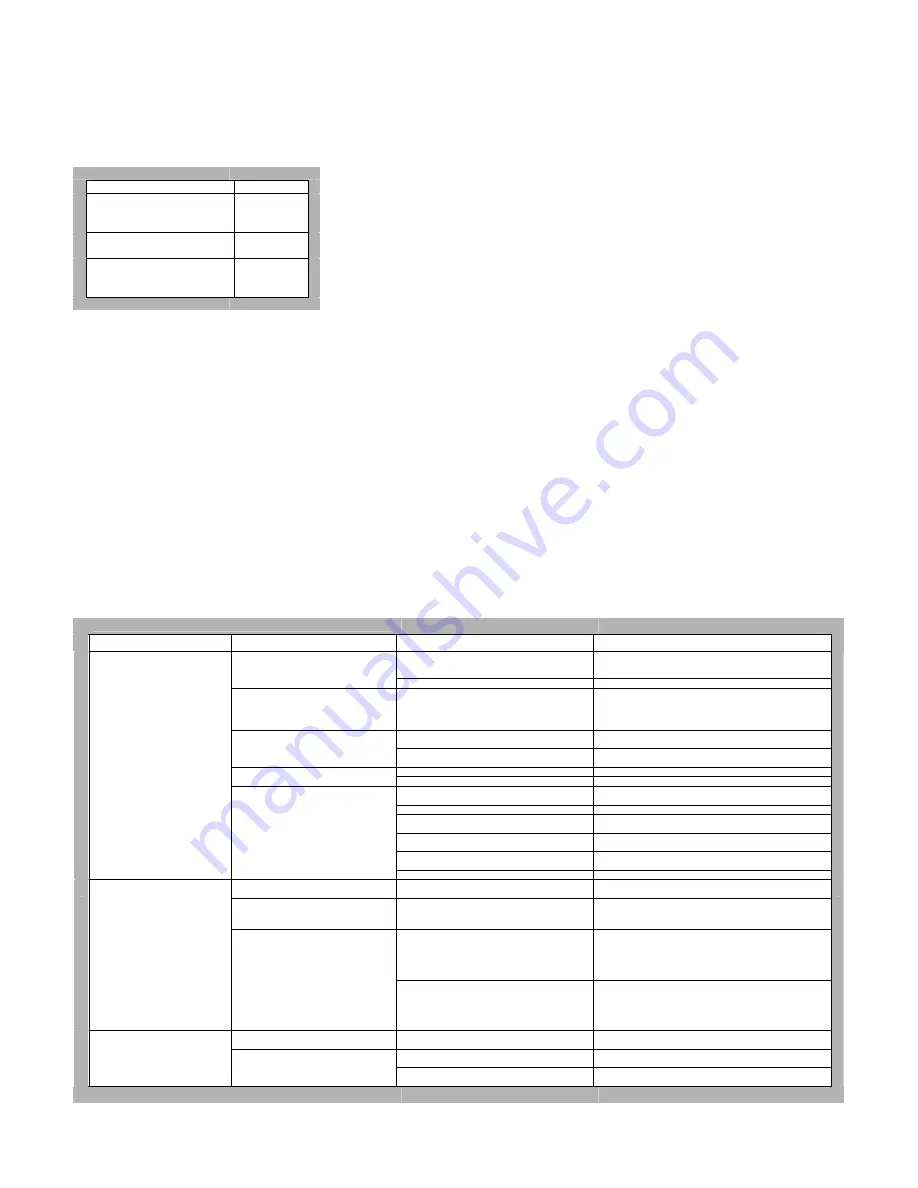

12. Troubleshooting

Malfunction

Conditions

Causes

Remedy

The temperature inside the enclosure is lower than

what is set on the adjustment thermostat.

This is not a malfunction of the cooling unit. To verify functioning

when testing, lower the thermostat setting until the compressor

and external fan start working and then reset the thermostat.

The internal fan works, the external fan and

compressor do not work.

The adjustment thermostat has failed

Change the adjustment thermostat

No component works

No electricity getting to the unit.

This is not a malfunction of the cooling unit.

•

Make sure the power cable has been connected well to the

terminals.

•

Check that the cubicle doors and switches are closed

Cooling unit empty of fluid

Call a refrigeration expert or the Manufacturer’s Technical Assis-

tance Service

Compressor, external and internal fan work

Compressor mechanical failure

Call a refrigeration expert or the Manufacturer’s Technical Assis-

tance Service

Internal fan capacitor failed

Change the internal fan’s capacitor

Compressor and external fan work, internal

fan does not work

Internal fan failed

Change the internal fan

Compressor’s amperometric protector failed (external

to the compressor, where present)

Change the amperometric protector

Relay or PTC for compressor starting failed

Change the relay or PTC for compressor starting

Capacitor for compressor starting failed (where pre-

sent)

Change the capacitor for compressor starting

Compressor motor electrical failure

Call a refrigeration expert or the Manufacturer’s Technical Assis-

tance Service

High pressure safety switch failed

Call a refrigeration expert or the Manufacturer’s Technical Assis-

tance Service

It fails to cool

External and internal fan work, compressor

does not work

Compressor contactor failed (where present)

Change the contactor

External and internal fans work, compressor

works all the time

Cooling unit under sized for the heat dissipated inside

the enclosure

Change the cooling unit with another of greater capacity

Inside fan works, external fan and compres-

sor work irregularly

Insufficient gas in the cooling unit

Call a refrigeration expert or the Manufacturer’s Technical Assis-

tance Service

High pressure safety switch triggered:

•

Ambient temperature over the maximum work-

ing limit

•

Heat exchanger coil (condenser) either dirty or

clogged

•

Ventilate the premises where the enclosure is installed to

keep ambient temperature lower.

•

Clean the exchanger with compressed air and detergent

It is not cooling enough

External and internal fans work, compressor

works irregularly

Thermal protector inside the compressor triggered:

•

Ambient temperature over the maximum work-

ing limit

•

Heat exchanger coil (condenser) either dirty or

clogged

•

Ventilate the premises where the enclosure is installed to

keep ambient temperature lower.

•

Clean the coil with compressed air and detergent

Enclosure door open

Too much ambient air inside the enclosure

This is not a malfunction of the cooling unit. Close the enclosure

door or disable the cooling unit

Enclosure protection level is below IP54

This is not a malfunction of the cooling unit. Seal enclosure open-

ings, e.g. for passage and upward path of wires

Too much condensate forming

Enclosure door closed

The enclosure/cooling unit connecting seal has been

fitted incorrectly

Check seal and remedy