Gamma

instabus

Technical product information

June 2014

Gamma arina touch sensor single

double

quadruple

Technical product information

UP 20x, UP 28x/3 and UP 28x/5

Update: http://www.siemens.com/gamma

Subject to change without further notice

Siemens Building Technologies

2.16.1.13/8

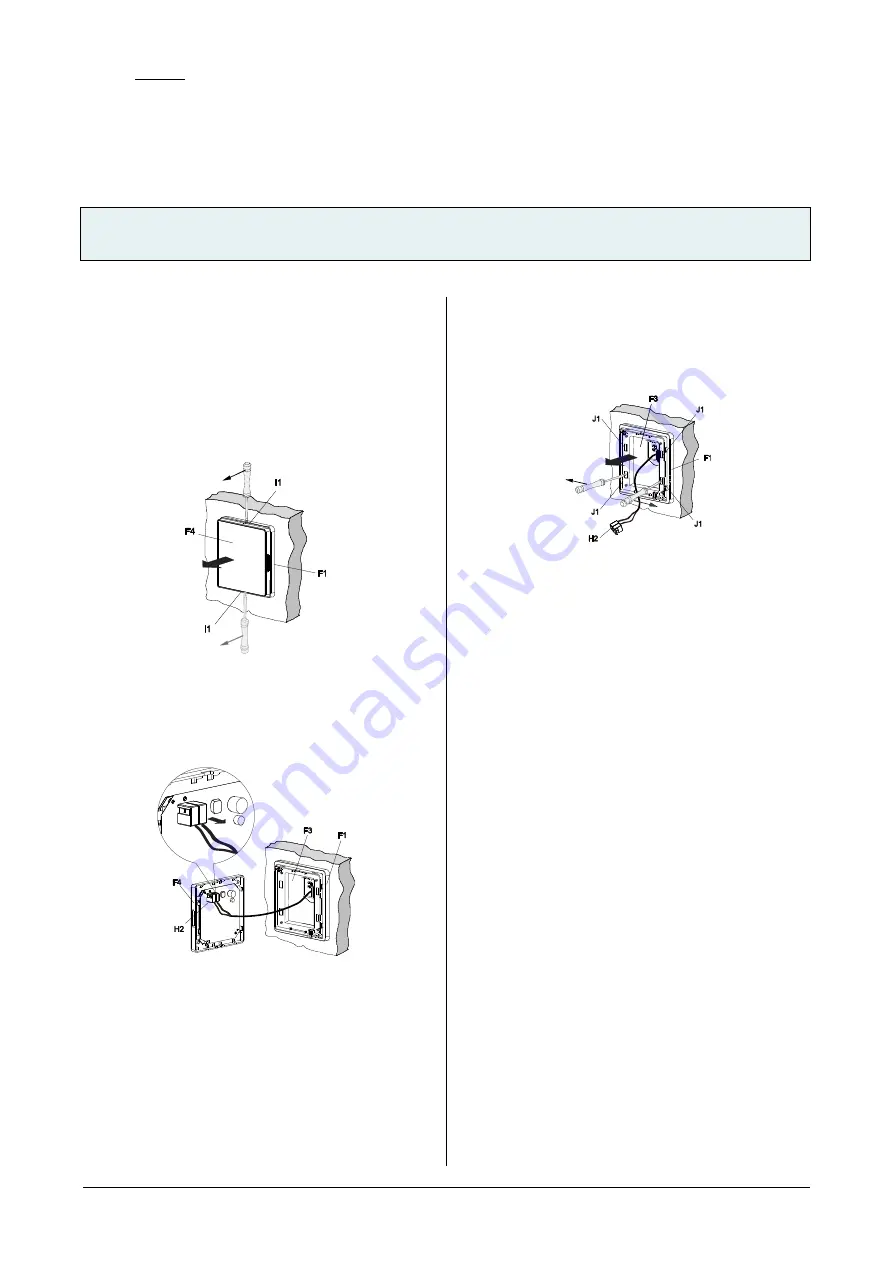

Unmounting

Remove the front housing (F4)

−

Remove the front housing (F4) of the touch sensor

apart from the back housing (behind the front cover

and invisible) with a screw driver, with the back hous-

ing still on the mounting frame (F1)

−

Pull off the KNX connector manually from the front

housing

Figure 7: Remove the front housing

F1

Mounting frame

F4

Front housing

I1

Hole for screwdriver

Figure 8: Remove the KNX connector

F1

Mounting frame

F3

Back housing

F4

Front housing

H2

KNX connector

Remove the back housing (F3)

−

Insert screwdriver to the holes (J1), and press as

showed in Figure 9.

−

Move the back housing out of the mounting frame (F1).

−

Pull the KNX connector (H2) out from the back housing.

Figure 9: Remove the back housing

F1

Mounting frame

F3

Back housing

H2

KNX connector

J1

Hole for screwdriver

Address assignment

−

Press the programming button (F5) on the device to

initiate the assignment of the physical address to the

device (figure 1).

−

The programming LED (E4) turns on to indicate the

programming mode. Upon receiving the physical ad-

dress the device automatically returns to normal oper-

ating mode and the LED turns off. The programming

LED is not invisible when turns off.