Page -4-

Copyright 2013 ShopBot Tools, Inc

Vacuum hold-down systems

A well-sealed vacuum system can be one of the most convenient and effective hold-down methods. It is ideal for

repetitive cutting of plywood and other large sheet materials.

Shopbot offers several kits for full-table vacuum systems on our Gantry tools. For other models (or small projects)

it is possible to build your own. This document is only meant as an introduction to hold-down systems, so we

won’t get into the details of that here. There are many resources online for both commercially available and DIY

vacuum systems. A google search for “CNC vacuum hold-down” will get you started.

Holding small parts within the material

Once you secure your material, you still need to consider what will happen to parts as you cut them out. Large

parts may shift as they are cut free, leading to a small gouge or notch along the edge. Smaller parts can be

destroyed or thrown by the cutter.

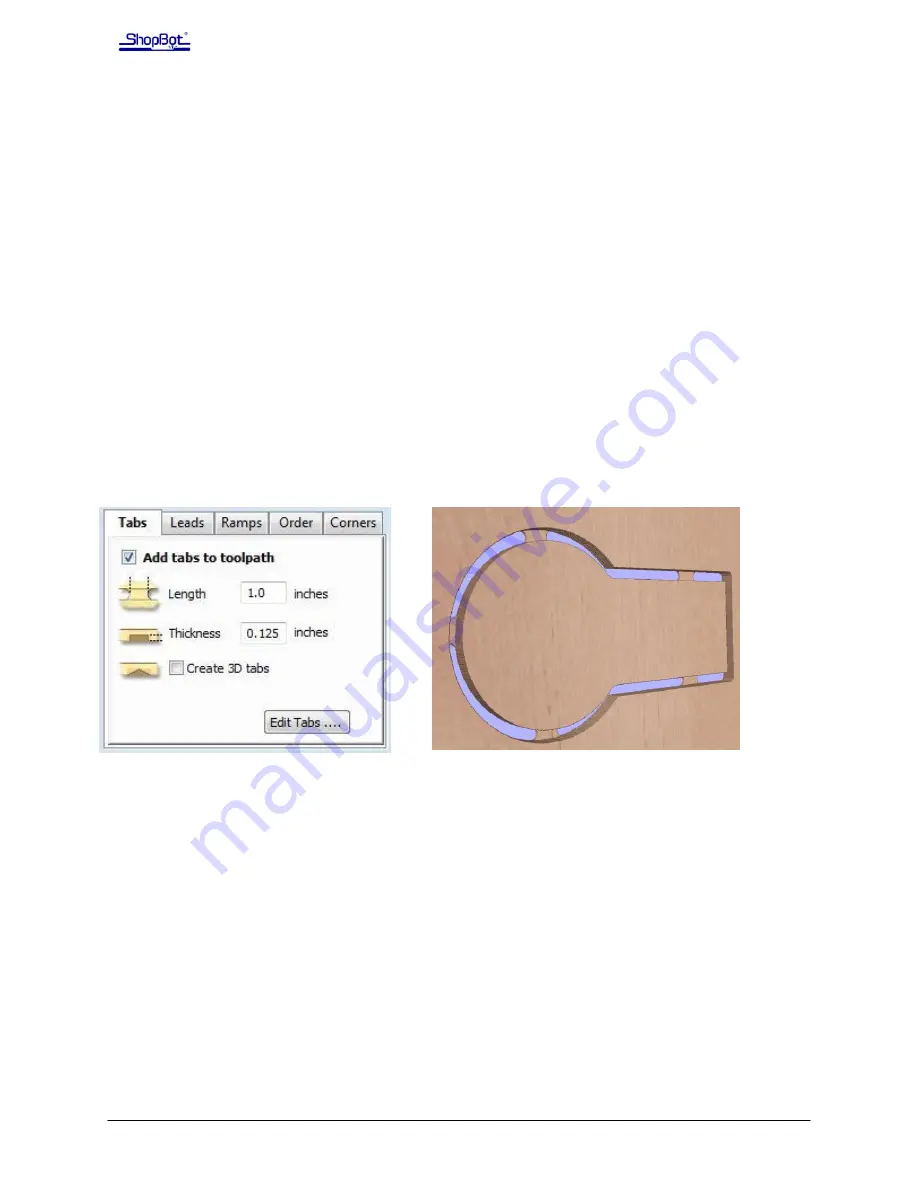

There are two ways that you can handle this from within the software. The first option is to create tabs, or leftover

“bridges” of material between the part and its surrounding area. Most CAM programs will have an automated

feature for this. The feature for Partworks/ V-Carve Pro / Aspire is shown here.

Adding tabs in V-Carve Pro

Example of tabs on a part

A second option is to leave an “onion skin,” or very thin layer of material at the bottom of a profile cut. Just set the

final cut depth at slightly less than the thickness of your material (typically .010” - .030”, depending on material and

size). The advantage is that the onion skin provides better hold and can be easier to trim/sand away than a series

of thick tabs. However, if there is a lot of variance in the thickness of your material, or if your table is not flat, then

you may end up cutting too deep or too shallow and this method will not work correctly.

Summary of Contents for HandiBot

Page 18: ......