If a Contact Line fault (number 4) is indicated,

check that resistors are

tted in all unused conditions on

the internal transmitter, that the termination boards are

tted and the cabling between termination board and

transmitter is not short or open circuit.

If a Power Failure (number 2) is indicated, check

the 230Vac supply to the panel and the two fuses on the

power supply board.

When all panels are on, each condition in turn

should be created at the plant to con

rm the operation

and setting of the system. When it is not possible to

create a condition e.g. from a pressure switch on a

pipeline which is in use, disconnect the condition on the

plant side of the termination board to simulate condition

faults.

When satis

ed that all conditions operate

correctly, anti confusion tests must be

carried out by creating alarm conditions on

each service in turn and con

rming that

each panel on which the service is displayed

operates correctly.

Section 7

OPERATION

All that is required for routine operation is for

sta

to mute the audible alarm on alarm panels in their

areas as required, taking any action required by the

nature of the service fault. The audible will resound

periodically as long as the service fault remains,

requiring re-muting.

When a condition is to be at alarm condition for a

long time, the audible can be continuously muted as

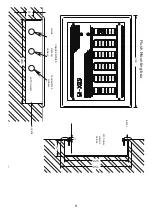

follows. Open the panel and, while the alarm condition is

present, press the white push button on the rear of the

control board.

Note that any other conditions present at the

time will also be locked out. Close the panel and con

rm

that the condition has been successfully locked out by

pressing the test button. All other lamps should

ash,

the locked out condition(s) being steady. The lockout will

cancel as soon as the condition returns to normal.

NOTE. This operation should only be carried

out by service personnel.

TESTING

Periodically operate the test button and

ensure that all lamps illuminate and the audible

sounds. Periodically disconnect the mains sup ply

to each panel and ensure that the system fault

lamp

ashes and the audible sounds. Provided

that the battery in the panel under test is sound

and fully charged, no other panel will be a

ected

by this test. Any remote audible connected to the

alarm panel under test will sound.

6

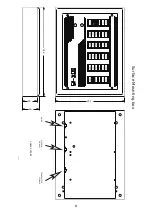

<R C>

B

M

ON

1

2

3

4

3

<R C>

AUDIBLE SELECTOR SWITCH

CHANNEL SELECTOR SWITCH

LOCKOUT BUTTON

CENTRAL/REPEATER SELECTOR JUMPER

POWER FAILURE SELECTOR

JUMPER SHOWN SET FOR

SYSTEM FAILURE LAMP

ONLY

HINGE CLIP

ON

1 2

3 4

4

ON

1 2

3

4

2

ON

1 2

3

4

3

ON

1

2

3 4

1

ON

1 2

3

4

0

CONTROL

BOARD

B

M

SDXPIC2

VOLUME CONTROL

SHOWN AS CENTRAL