is design to be used WITHOUT termination boards.

Again the service channel is selected with a

rotary switch and the connection to the plant (or

manifold) is similar to the internal transmitter, only there

is no requirement for the Termination Board.

A 230Vac, 50/60 Hertz supply is required.

Note. This is the only item on the SDX-15

system which does not include a mains

termination cover. Note the warning label

on the outside of the box.

The 2 core inter-panel wiring is connected to

signal terminals 1 & 2. The cable screen must be

connected to and earth point or to the circuit earth.

COMPUTER INTERFACES.

Computer Interfaces are available which will give

volt-free contacts which are closed when a condition is

at normal. The relays are grouped in blocks of four,

giving four conditions plus normal, which is closed only

when all four conditions on that service are at normal.

The services are selected, as in the alarm panel, with a

rotary switch. However, the computer interface has only

one switch for up to 5 services. This switch is set to the

rst service required and the other services will follow in

sequence. e.g. if the switch on a 3 service interface is

set to channel 2 then the services detected will be

channels 2, 3,4 &5.

The computer interface is a self contained unit,

supplied as a 1, 2, 3, 4 or 5 service unit. A 230Vac, 50/60

Hertz supply is required, which is connected to terminals

under the mains terminal cover. The 2 core inter-panel

wiring is connected to signal terminals 1 & 2. The cable

screen must be connected to the ``S'' terminal.

The rating of the relay contacts is 0.5amp, 24V

dc resistive.

NOTE. Each SDX-15 central or repeater alarm

has an integral common alarm relay

tted as standard.

This relay opens when any alarm condition or fault

occurs on the panel and is similarly rated.

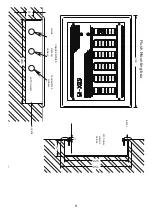

PLANT TO ALARM INTERFACE.

The plant to alarm interface is a low cost means

of complying with the C11 & HTM02-01 requirements for

indication of alarm status in plant or manifold room. It is

mounted in a clear fronted polycarbonate enclosure

protected to IP65, making it weatherproof and suitable

for use in VIE compound etc. with no further protection.

It consists of the following.

Four alarm conditions plus normal Power On &

system fault lamps. A one gas transmitter, connected to

the plant & set to the required channel in the same way

as a standard transmitter. Four relays, giving volt-free

contacts, closed under normal conditions, for connection

to other alarm systems, BMS systems etc. A battery

reserve to power the system failure lamp and the

transmitter in the event of power failure.

The plant to alarm interface requires a 230Vac,

50/60 Hertz supply and connection to the two core inter-

panel wiring.

Note. Being a basic indicator, the plant to alarm

interface has no audible alarm or test facility. Refer to

the instruction sheet supplied with the plant to alarm

interface for further details.

Section 5

SYSTEM DESIGN

If in doubt, please contact the

manufacturers. Errors can easily be recti

ed at

this stage.

The system must consist of a single central

panel, which should be mounted in a area which is

manned 24 hours a day. Select the number, location and

size (number of services to be displayed) of alarm panel

as required by C11/HTM02-01.

Select the location and size of transmitters. Use

internal transmitters if an alarm panel is in the same

room as the plant, or a remote transmitter if no

additional local indication is required.

Remember that a plant to alarm interface is

cheaper than a one service repeater with internal

transmitter for locations where local indication is

required.

With more than one service, a repeater with

transmitter is more economical. The distance between

the plant and the transmitter should be kept to a

minimum, and in any case should not exceed 100

metres.

See section 4 if conditions of a service are to be

transmitted from more than one location.

Transmitters are supplied with termination

boards, which must be mounted in or adjacent to the

plant.

Select Computer interfaces as required.

Section 6

SETTING UP

WARNING. STATIC SENSITIVE DEVICES.

OBSERVE HANDLING PRECAUTIONS.

Set the alarm panel at the central location as a

central by placing the jumper between the centre & right

hand pins on the central selector. Ensure that all other

panels have the jumper between centre & left hand pin.

Set the power failure mode as required using the

jumper adjacent to the ribbon cable connector. If the

any alarm panel is to have full battery operation under

power failure conditions, place the jumper between the

centre and lower pins on the power selector.

Allocate a channel for each service and enter the

name of the service on the log sheet in the “Gas

Service'' column. It may be useful to allocate the

services in the order in which they appear on the central

panel, although this is not necessary. Go to each

internal transmitter and set the rotary switch for each

service to the channel allocated to that service on the

log sheet. Set the rotary switch on each remote

transmitter to the channel allocated to the

rst service

on this transmitter. Set the channel for each computer

interface as for remote transmitters.

Set the rotary switch on each plant to alarm

interface to the appropriate channel. For each alarm

panel, set the rotary switch for each service displayed on

the panel to the channel allocated to that service.

If a column is not required e.g. if a spare service

has been installed for future use, set the rotary switch to

``F'' which switches o

that column.

Set the four audible switches for each service as

required (switch number 1 is condition 1, the

rst lamp

below normal. If a switch is on, the audible for that

condition will operate, otherwise it will never sound).

Mount the front plate & PCB onto the hinge by

springing the ends of the hinge apart &

tting into the

clips on the PCB.

Plug the ribbon cable on the power supply into

the control PCB. (it is keyed to prevent incorrect

connection).

Switch on the power to all panels, transmitters

etc. and connect the battery cables, observing polarity.

The system should now be operational.

No panels will operate if the central panel is not

functioning. In this case, all repeater panels will show an

Incoming Signal (number 1) on the system fault display

when the test button is pushed.

This will also happen if the inter-panel wiring is

reversed at any panel or the wiring is short circuited.

Disconnect each panel in turn until the fault

clears. If it does not, check for short circuits.

5