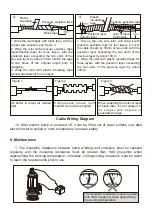

Plastic

insulating

tape

Pressure sensitive tape

Black tape

Plastic

insulating

tape

Pressure sensitive tape

Anterior layer

Posterior layer

Joint of three

conductors

1. Wrap the joint tightly with black tape, with no

copper wire exposed, see Figure 3.

2. Wrap the joint with pressure sensitive tape

(self-adhesive tape) for three layers, with the

posterior layer exceeding the two ends of the

previous layer by about 10mm; stretch the tape

to two times of the original length prior to

wrapping.

3. Wrap the joint with plastic insulating tape

(yellow transparent) for one layer.

1. Tidy up the core wire joint, and wrap it with

pressure sensitive tape for four layers to cover

the cable sheath by 30mm at two ends, with the

posterior layer exceeding the two ends of the

previous layer by about 10mm.

2. Wrap the joint with plastic insulating tape for

three layers, with the posterior layer exceeding

the two ends of the previous layer by about

10mm.

Figure 1

Figure 2

Figure 3

It's better to adopt air welded

joint

Cold-pressed sleeve joint

method can also be adopted

When wrapping the anterior layer

of black tape, it's not allowed to

l e t c o p p e r w i r e e x p o s e o r

penetrate the tape

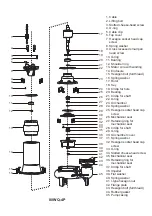

Cable Wiring Diagram

15. After electric pump is powered off, it can be lifted out of water surface only after

electric motor is cooled to room temperature to ensure safety.

V. Maintenance

1. The insulation resistance between pump winding and enclosure shall be checked

regularly, and the insulation resistance must be greater than 1MΩ (megohm) when

approaching the working temperature; otherwise, corresponding measures must be taken

to reach the requirements prior to use.

The insulation resistance must be greater

than 1MΩ (megohm) when approaching

the working temperature