10. For electric pumps not used with total lift (the upper and lower limits of lift are

specified), they must be used within the usable range of lift to avoid damage of electric

pumps due to overload. For electric pumps used with total lift, the pipe diameter adopted

shall be consistent with but not greater than the specified pipe diameter to avoid overload.

11. Electric pumps are of dry structure, and it's not allowed to fill the cavity of motor with

oil or water.

12. The oil chamber of the product is filled with No.10 white oil for food-level machinery

to ensure that mechanical seal is lubricated and cooled effectively, and leakage may occur

when the product is damaged or out of order. In such service environment as plantation,

cultivation, or delivery and processing of drinking water or food, leaking white oil may cause

damage to planted plants or farmed animals or pollute drinking water or food. The user

shall evaluate the service environment and the consequence of using the product prior to

selection and use of the product to confirm whether the product is applicable, and shall

invite related professionals for confirmation where necessary. In case of leakage of white

oil, the user shall immediately stop using the product and handle it properly.

13. When electric pump is running, if it is needed to adjust the position of electric pump

or touch the electric pump, the power must be disconnected first to avoid accidents.

Power must be

disconnected

when in touch

with electric pump

ON

OFF

ON

OFF

ON

OFF

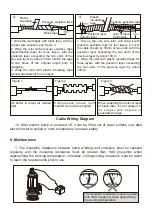

14. When electric pump is running, it's strictly prohibited to immerse cable joints or plug

boards into the water; if this is needed for extension of cable, the joints shall be sealed and

covered strictly to avoid electric leakage due to water seepage. (Refer to the figure below)

1 . R e m o v e t h e

insulating layer without

damaging conductor

2 . S t a g g e r s e v e r a l

conductors in length

3. Ensure no oil, water

or other dirt at the joint

No less than 10 times of conductor diameter

1. Tighten up the joint by

dividing it into several

strands evenly (at least 6

strands).

2. Cross two joints by such

a length that the wire ends

reach the insulating layer at

both ends.

1. Tighten up the strands together, take out

one strand from the middle and twine it to

one end (the twined core wire contains the

other strands), and then twine other strands

one by one.

2. Repeat the step above at the other end.

3. Tighten the joint with pliers, and coat the

joint with tin to achieve the best effect.

Note: See the attached figure 1 and

attached figure 2 for other methods