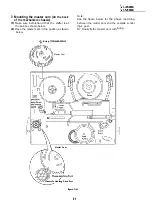

Push the

or tracking button to check

that

a

flat response is obtained on the

envelope waveform.

the guide roller by tightening the

guide roller setscrew in the unloading mode.

Play back the tape drive train alignment tape

to check that the envelope waveform does

not change.

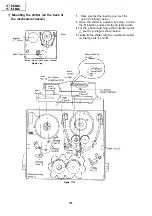

Adjustment of A/C head X-position.

a) In the X value adjustment mode (see the

Electrical Adjustment), make a short circuit

between

and

both located at

the on your side on the VCR

with a

ohm resistor to center the tracking.

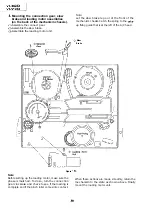

Rotate the X-position adjusting nut with an

adjusting box driver, and adjust the A/C head

position for maximum head switching pulse

low side envelope.

Adjust the playback switching point.

Check the flatness of the envelope waveform

and sound by playing back a recorded tape.

X-position adjusting nut

Main chassis

Figure

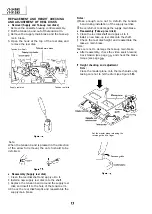

REPLACEMENT OF THE CAPSTAN

(DIRECT DRIVE) MOTOR

Remove the cassette housing control assembly.

R e m o v a l ( F o l l o w t h e o r d e r o f i n d i c a t e d

numbers.)

Disconnect from the board-to-board connector

on the VCR

Remove the reel belt

Remove the screws

Figure

Figure

l

Reassembly

Mount the capstan motor on the mechanism

chassis making sure not to allow the capstan

shaft to hit the mechanism chassis, and attach it

with the three screws.

Attach the reel belt. Reconnect to the board-to

board connector on the VCR

Notes :

After installing the capstan

motor, be sure

to rotate the capstan

motor and check the

movement.

Check the servo circuit.

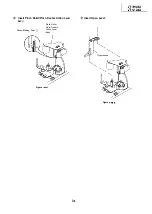

REPLACEMENT OF

MOTOR

Put the unit in the cassette eject position.

Unplug the power cord.

l

Removal (Reverse the order in reassembly.)

Disconnect the

cable

Unscrew the

assembly fixing screws

Take out the

assembly

Unscrew the rotor assembly fixing screws

Take out the rotor assembly

Notes:

In removing the

assembly, part of the

drum earth spring pops out of the

collar.

Be careful not to lose it.

Secure the

rotor assembly so that the

installation positioning holes in the rotor

assembly and upper drum assembly match.

(Match the upper drum’s notch with the rotor’s

hole.)

Be careful not to damage the upper drum or the

video head.

Be sure that the hall device and the

assembly are not damaged by the rotor assembly

or other parts.

After installation, adjust the playback switching

point.

2

motor

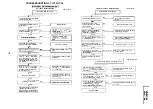

Summary of Contents for VT-3428X

Page 78: ...m 3428X VT 51 28X IF Pack Unit RiWOOl7CEZZ 1 4 11 l e i t 1 I 2 I 3 I 4 I 5 I 6 1 78 ...

Page 82: ...VT 3428X VT 5128X I AWIO m I Au 10 f X I 7 I 8 I 9 I 10 I 11 I 12 I 82 ...

Page 90: ...VT 3428X VT 51 28X I t 7 I 8 I 9 I 10 I 11 I 12 I ...

Page 94: ...VT 3428X W 5128X 3 7 I 8 I 9 I 10 I 11 I 12 I 94 ...

Page 96: ...VT 3428X VT 51 28X TO Y C AUDIO CIRCUIT NCR 21 I I I I 7 I 8 I 9 I 10 I 11 I 12 I 96 ...

Page 100: ...m 3428X VT 51 28X Wiring Side f r 7 I 8 I 9 I 10 I 11 I 12 1 100 ...

Page 102: ...VT 3428X VT 51 28X I 7 I 8 I 9 I 10 I 11 102 1 12 I ...

Page 104: ...VT 3428X I m 5128X 1 7 I 8 I 9 I 10 I 11 I 12 I ...

Page 123: ...MECHANISM CHASSIS PARTS G F E I i 1 I 2 I 3 I 4 I 5 I 6 I 123 ...

Page 125: ...CASSETTE HOUSING CONTROL PARTS i T 3428X VT 51 28X 1 I 2 I 3 I 4 I 5 I 6 I 125 ...

Page 127: ...VT 3428X W 51 28X MODIEL VT 3428X CABINET AND MECHANICAL PARTS 1 I 2 I 3 I 4 I 5 I 6 127 ...

Page 128: ...W 3428X VT 51 28X I IO 9 0 3 7 128 ...

Page 130: ...VT 3428X VT 5128X I 0 I 0 ...

Page 132: ...MODELS VT 3428X AND VT 51 28X CABINET AND MECHANICAL PARTS I i 1 I 2 I 3 I 4 I 5 I 6 I 132 ...

Page 136: ...S H A R P TQ0023 S Printed in Japan 0 w s MW KD ...