5) Remove the PRINTER LID

.

a) Remove the screw

.

b) Remove the PRINTER LID

.

6) Install the PAPER ROLLERs (4ea.)

.

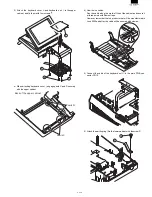

Fig. 3

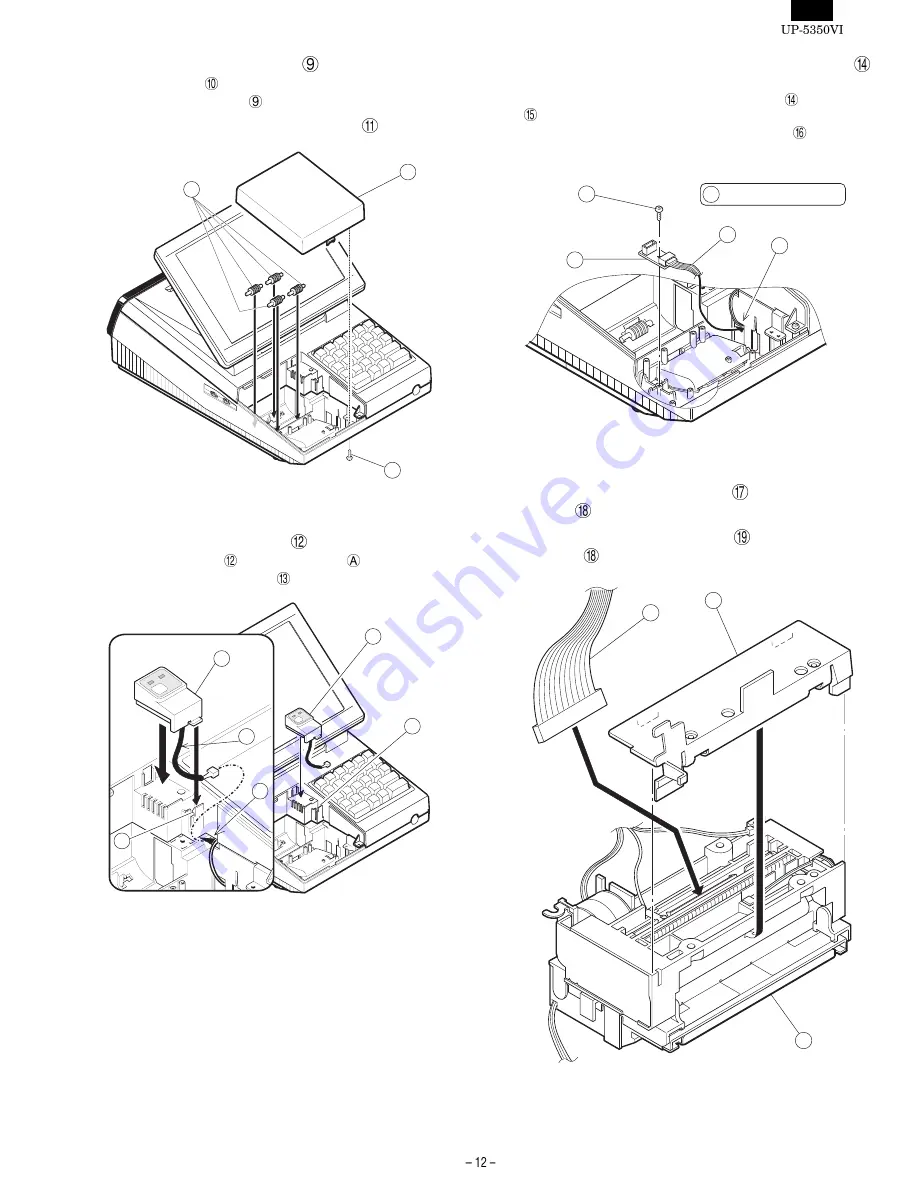

7) Install the SWITCH UNIT

.

a) Fix the SWITCH UNIT

on the cabinet pawl

.

b) Pass the SWITCH UNIT CABLE

through the hole (B).

Fig. 4

8) Install the AUTO CUTTER RELAY PWB UNIT

.

a) Install the AUTO CUTTER RELAY PWB UNIT

with SCREW

.

b) Pass the AUTO CUTTER RELAY PWB CABLE

through the

hole (C).

Fig. 5

9) Install the PAPER GUIDE

to the PRINTER

UNIT .

10) Install the HEAD CABLE

to the PRINTER

UNIT .

Fig. 6

10

9

11

12

A

A

B

12

13

14

15

C

16

: XEBSD30P08000

15

17

19

18