R343M - 5

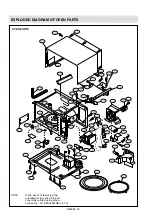

DOOR OPEN MECHANISM

FUNCTION OF IMPORTANT COMPONENTS

Figure D-1. Door Open Mechanism

LATCH

HEADS

LATCH HOOK

MONITOR

SWITCH (SW2)

MONITORED

LATCH

SWITCH (SW1)

STOP

SWITCH

(SW3)

DOOR OPEN BUTTON

OPEN LEVER

DOOR

MONITORED LATCH SWITCH SW1

STOP SWITCH SW3

1. When the oven door is closed, the contacts (COM-

NO) must be closed.

2. When the oven door is opened, the contacts (COM-

NO) must be opened.

MONITOR SWITCH SW2

I

f the oven door is opened and the contacts

(COM-NO) of the monitored latch switch SW1

fail to open, the fuse F8A blows

simultaneously with closing the contacts

(COM-NC) of the monitor switch SW2.

CAUTION: BEFORE REPLACING A BLOWN

FUSE F8A TEST THE MONITORED

LATCH SWITCH SW1, MONITOR

SWITCH SW2.

MICROWAVE OUTPUT POWER (IEC-60705)

The power output of this oven is rated using the method specified by IEC-60705. Full details of how to carry out this

procedure can be found in the Sharp Technical Training notes which is available from Sharp Parts Centre

(part number SERV-LITMW01).

The IEC-60705 procedure must be carried out using laboratory-type procedures and equipment. These requirements

make the procedure unsuitable for routine performance checks.

Note: The following test method gives an indication of the output power only, it cannot be used to establish the actual/

rated output power. If the true output power is required, then the IEC-60705 test method must be used.

Alternative simplified method:

1. Place 2 litres of cold water (between 12

°

C and 20

°

C) in a suitable container.

2. Stir the water and measure the temperature in

°

C. Note temperature as T1.

3. Place the container in the microwave and heat the water for 2 minutes on full power.

4. When the 2 minutes is completed, remove the container and stir the water. Note the water temperature as T2.

5. Calculate the output power using the following formula:

R.F. Power Output = (T2 - T1) x 80.

MICROWAVE LEAKAGE TEST

This oven should be tested for microwave leakage on completion of any repair or adjustment, following the procedure

described in the Sharp Technical Training notes (part number SERV-LITMW01). The maximum leakage permitted in

BS EN 60335-2-25 is 50W/m

2

(equivalent to 5mW/cm

2

), however it is not normal to detect any significant leakage,

therefore, any leakage which is detected should be investigated.

It is essential that only leakage detectors with current calibration traceable to the National Physical Laboratories are

used.

Suitable leakage detectors :

CELTEC A100

APOLLO X1

OUTPUT POWER TEST PROCEDURE

Summary of Contents for R-343GM

Page 23: ...R343M 23 NOTES ...