MX-M264U MX-M264U/M314U/M354U/M264N/M314N/M354N (MAIN UNIT) 2 – 3

C. Paper feed tray setup

(1) System setting

1)

Press the [SYSTEM SETTINGS] key.

2)

Touch the [Paper Tray Settings] key.

3)

Touch the [Paper Tray Settings] key to configure the settings.

These settings specify the paper type, paper size, and func-

tions allowed for each paper tray. When the [Tray Settings] key

is touched, a list appears showing the trays and the current

settings.

4)

Touch the [Change] key in the above screen to change the set-

tings. The following settings can be configured.

(2) Tray size setup

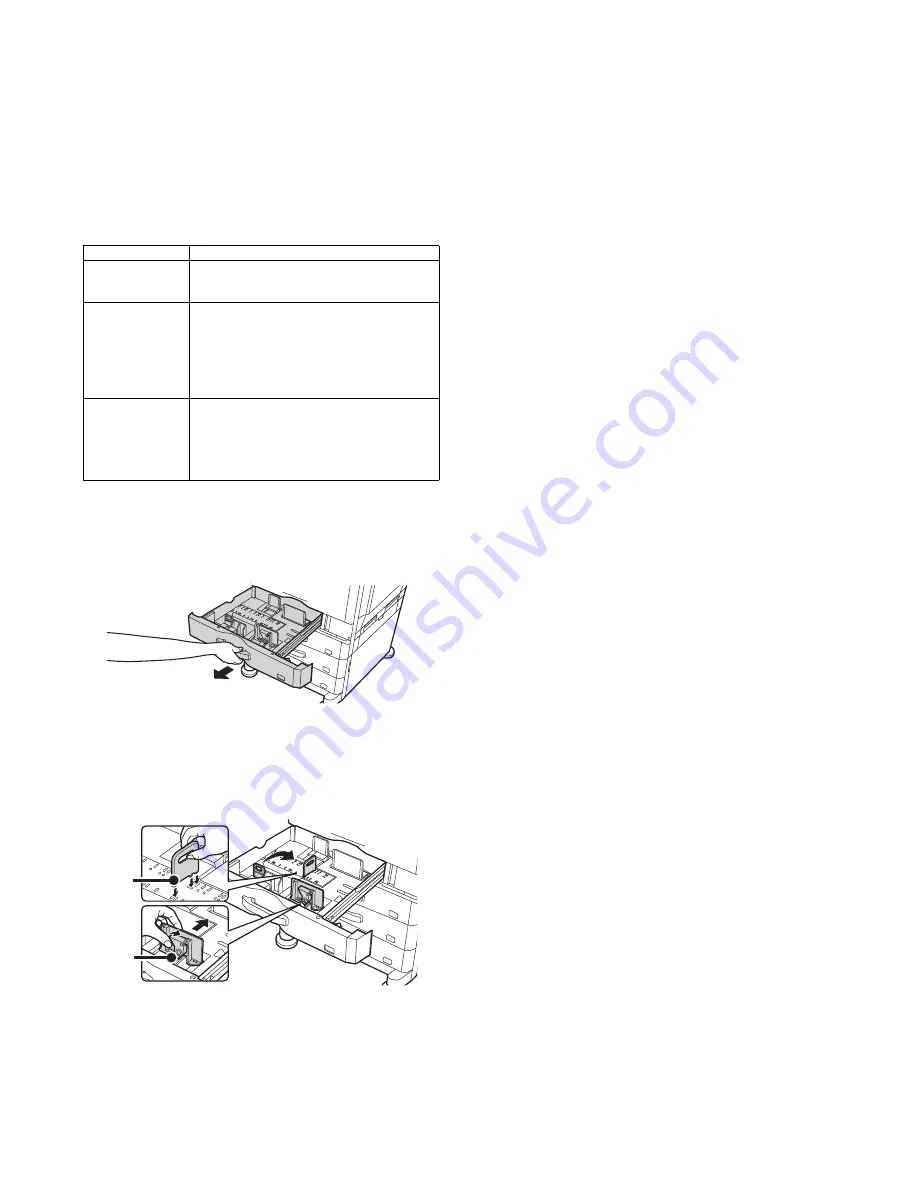

1)

Pull out the paper tray.

Gently pull the tray out until it stops.

If paper remains in the tray, remove it.

2)

Adjust the guide plates A and B by squeezing their lock levers

and sliding them to match the vertical and horizontal dimen-

sions of the paper to be loaded.

The guide plates A and B are slidable. Slide each guide plate

while squeezing its lock lever.

Item

Description

Type

Select the type of paper that is loaded in the tray.

The paper types that can be selected vary by paper

tray.

Size

Select the paper size from the list. The paper sizes

that can be selected vary by tray. The sizes that

can be selected may also be restricted by the paper

type selected above.

If the desired size does not appear in the list, select

[Custom Size] and directly enter the size (only for

the bypass tray).

Feeding Approved

Job

Select the modes that can be used. If there is a

function that you do not wish to be used with the

selected tray, disable the function. When the "Type"

is other than plain paper, recycled paper, colored

paper, or a user type, [Fax] and [Internet Fax]

cannot be selected.

A

B