AR-5316 SIMULATIONS 7-4

22

14

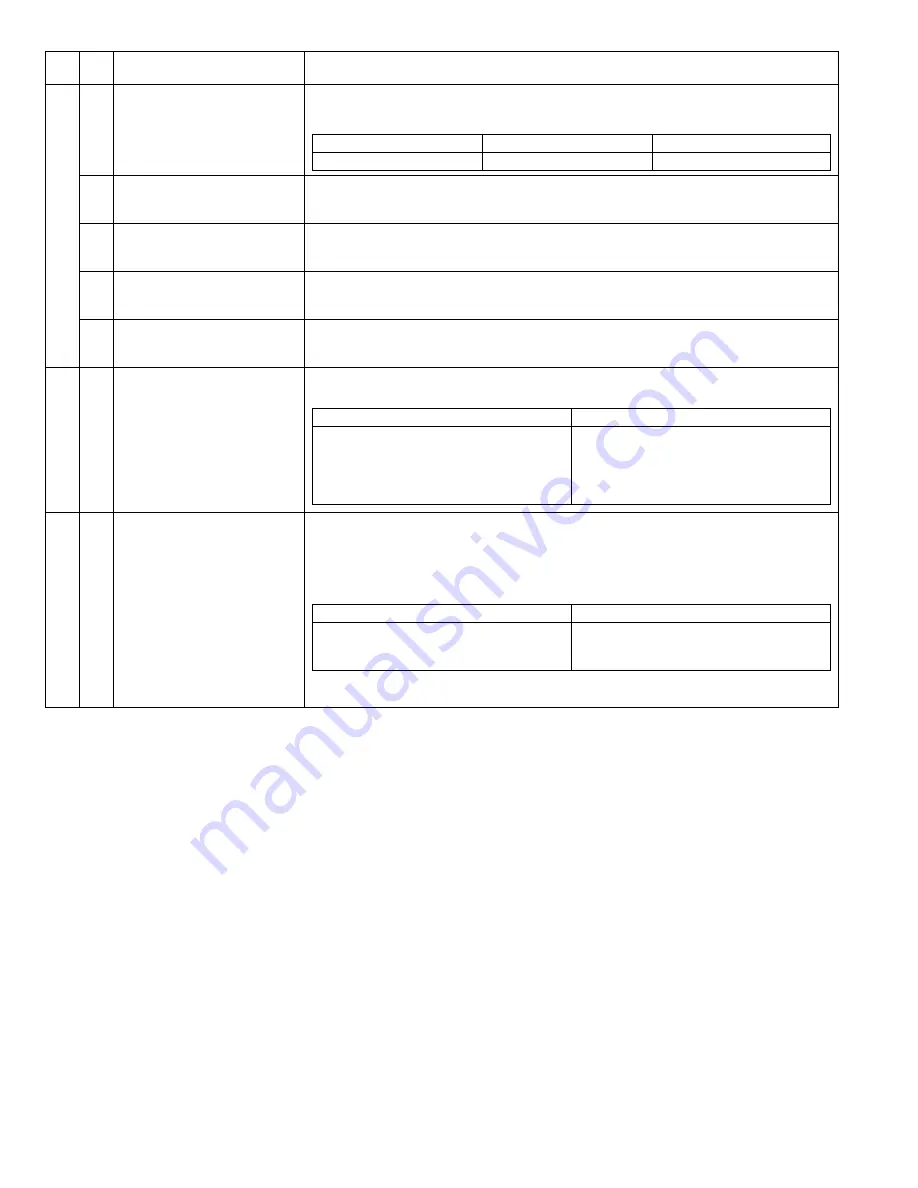

P-ROM version display

The P-ROM version is displayed on the copy quantity display. The main code and the sub code are

alternatively displayed by 2 digits. The display interval is same as that of the counter display.

By pressing the fixed magnification ratio key, each version display is switched.

17

Copy counter display

The copy counter value is displayed. (Alternate display by 3 digits) When the [Interrupt] key is

pressed, the machine goes into the sub code input standby mode. When the [CA] key is pressed, the

simulation is terminated.

18

Printer counter display

The printer counter value is displayed. (Alternate display by 3 digits)When the [Interrupt] key is

pressed, the machine goes into the sub code input standby mode. When the [CA] key is pressed, the

simulation is terminated.

21

Scanner counter display

The scanner counter value is displayed. (Alternate display by 3 digits)When the [Interrupt] key is

pressed, the machine goes into the sub code input standby mode. When the [CA] key is pressed, the

simulation is terminated.

22

SPF jam counter display

The SPF jam counter value is displayed. (Alternate display by 3 digits)When the [Interrupt] key is

pressed, the machine goes into the sub code input standby mode. When the [CA] key is pressed, the

simulation is terminated.

30

01

Paper sensor status display

The paper sensor status is displayed with the lamps on the operation panel.

*

When each sensor detects paper, the corresponding lamp turns on.

44

34

Transfer current setting

Used to set the transfer current for the front surface and that for the back surface. When this

simulation is executed, the current set value is displayed on the 7-seg display. Select the set value

with the zoom (Up/Down) keys and press the [START] key, and the set content is written into the

EEPROM and the machine goes into the sub code input standby mode. Press the [Mode select] key

to select each setting mode. At that time, the setup content is written into the EEPROM.

The set range is 90uA ~ 360uA in the increment of 10uA.

*

Small size paper must be Letter R (A4R) or smaller.

*

For the special size of tray, use the normal size width.

Main

code

Sub

code

Contents

Details of operation

Display lamp (AB series)

Display lamp (Inch series)

Displayed version

141%

141%

Machine program

Display lamp

Sensor name

Developer lamp

Toner lamp

Manual paper feed lamp

No. 1 cassette lamp

Zoom lamp

Paper exit sensor

Paper entry sensor

Manual feed paper empty sensor

No. 1 tray paper empty sensor

New drum detect sensor

Display lamp

Setting mode

AE mode lamp

AE mode lamp & PHOTO mode lamp

AE & TEXT & PHOTO mode lamps

Normal size width: Front

Small size width: Front

Manual paper feed

[07]SIMULATIONS.fm 4 ページ 2005年7月1日 金曜日 午後5時28分