UX-108U/178U/188U

FO-375U

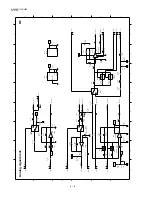

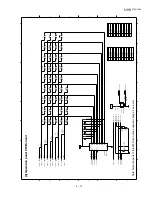

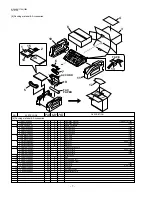

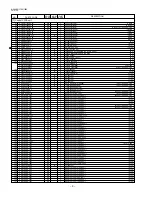

Relay

cable

CNLIUA

CHECK

CONTROL

PWB

TEL/LIU

PWB

12

1

CNPW

CNLIU

POWER

SUPPLY

PWB

•

The relay cables are used as one pair.

•

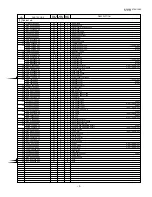

The sensor is wired as shown in the following figure.

•

The door swich and hook switch are manually operated.

8 – 2

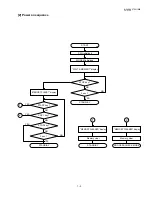

2. Description

2-1. Relay board unit

1. Remove the TEL/LIU PWB, control PWB and Power Supply PWB

from this unit, and mount the relay board unit instead.

•

Before connecting the wiring to the relay board unit, set the test

PWB switches to the fixed position.

2. The setting is as follows.

The recording paper sensor (PSNS) is operated by OR of the mechani-

cal unit switch and the test PWB switch. When performing installation in

the machine unit, set the test PWB switches to the fixed position.

Mechanical unit

PWB to be tested

Actual operation with mechanical unit

Recording paper

sensor

ON/OFF operation

OFF (Photo interrupter

is interrupted.)

PWB sensor check

Recording paper

sensor

ON/OFF operation

OFF

POWER

SUPPLY

PWB

TEL/LIU

PWB

CHECK

CONTROL

PWB

DOOR

SENSOR

RELAY CABLE

DON'T SEPARATE

UNIT

TP3

(PSNS)

TP3

(PSNS)

TP1(DG)

TP2(+5V)

C

K

A

E

These cables are connected from the extension board

and the checked control PWB at TP1 thru TP3 (signals

of DG, +5V and PSNS).

EXTENSION PWB

NOTE

Summary of Contents for FO-375

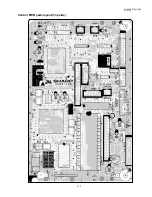

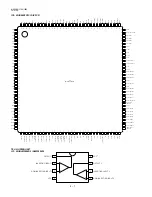

Page 61: ...6 7 UX 108U 178U 188U FO 375U Control PWB parts layout Top side ...

Page 62: ...6 8 UX 108U 178U 188U FO 375U Control PWB parts layout Bottom side ...

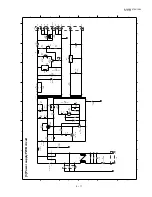

Page 64: ...6 10 UX 108U 178U 188U FO 375U TEL LIU PWB parts layout ...

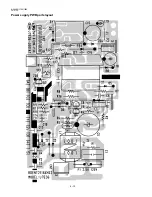

Page 66: ...6 12 UX 108U 178U 188U FO 375U Power supply PWB parts layout ...