11

2-4. Di p Switch Setting

The printer is set up at the factory to be appropriate for almost all users. It does, however, offer some

settings for users with special requirements.

It has DIP switches that allow you to change communication settings, such as handshaking and parity

check, as well as print density.

Your printer has two sets of DIP switches. The functions of the switches are shown in the following

tables.

♣

Note : Turn power off unplug the printer. Open the Dip Switch cover to change settings.

2-4-1. Serial Interface Specification

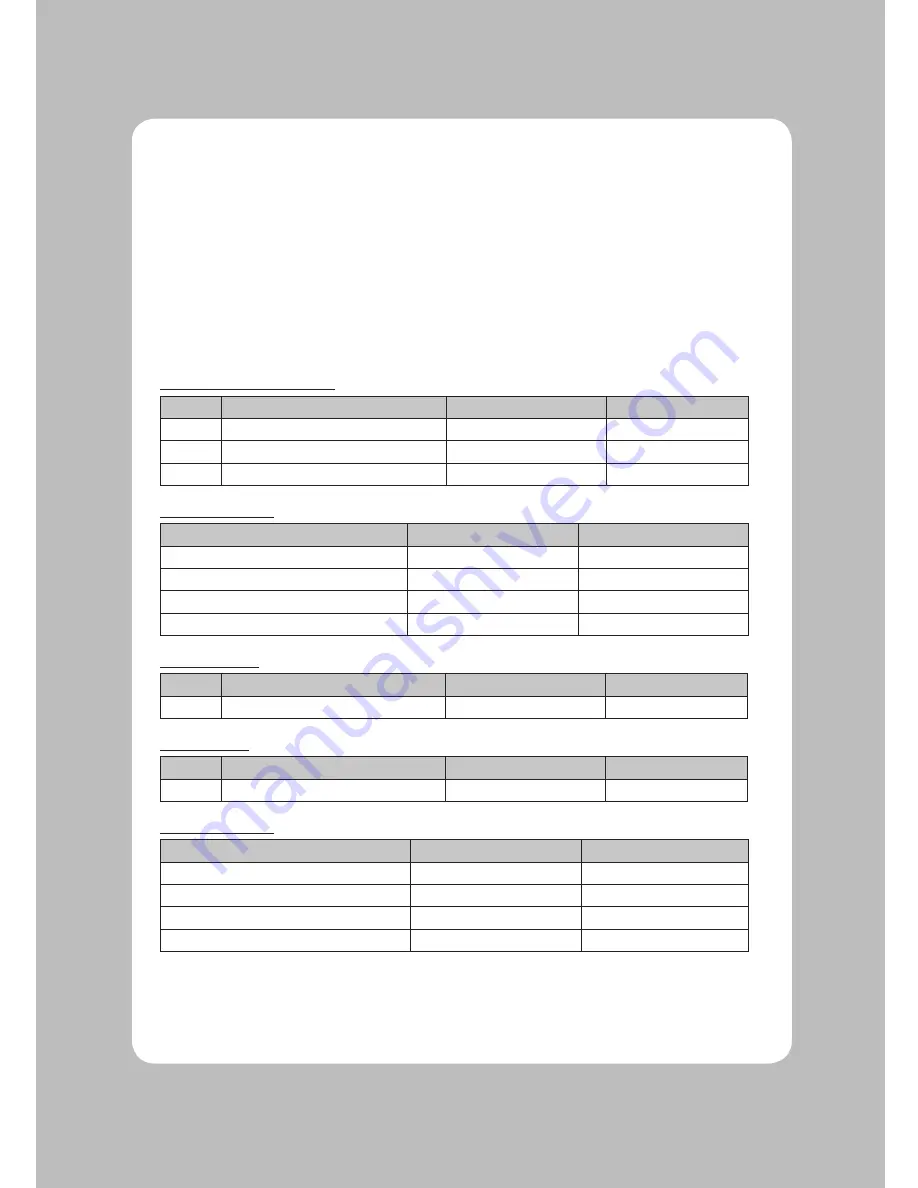

DIP Switch Setting (Standard)

SW

FUNCTION

ON

OFF

2

Hexadecimal

HEXDUMP

NORMAL

5

Cut Mode

Full Cut

Partial Cut

8

Paper Low Mode

Paper Low Detect

Do not detect

Baud rate selection

Function

SW-3

SW-4

Low Power

ON

ON

Normal

OFF

ON

Normal

ON

OFF

Dark

OFF

OFF

Parallel Interface

SW

FUNCTION

ON

OFF

6

Bi-direction Mode

Disabled

Enabled

Serial Interface

SW

FUNCTION

ON

OFF

6

Handshaking

XON/XOFF

DTR/DSR

Baud rate selection

Transmission Speed

SW-9

SW-10

115200 BPS

ON

ON

9600 BPS

OFF

ON

19200 BPS

ON

OFF

38400BPS

OFF

OFF

Summary of Contents for LK-T12

Page 1: ...Receipt Printer User s Manual MODEL LK T12...

Page 19: ...18 8 Overall dimension...

Page 24: ...23...

Page 25: ...24...

Page 26: ...25...

Page 27: ...26...