16

17

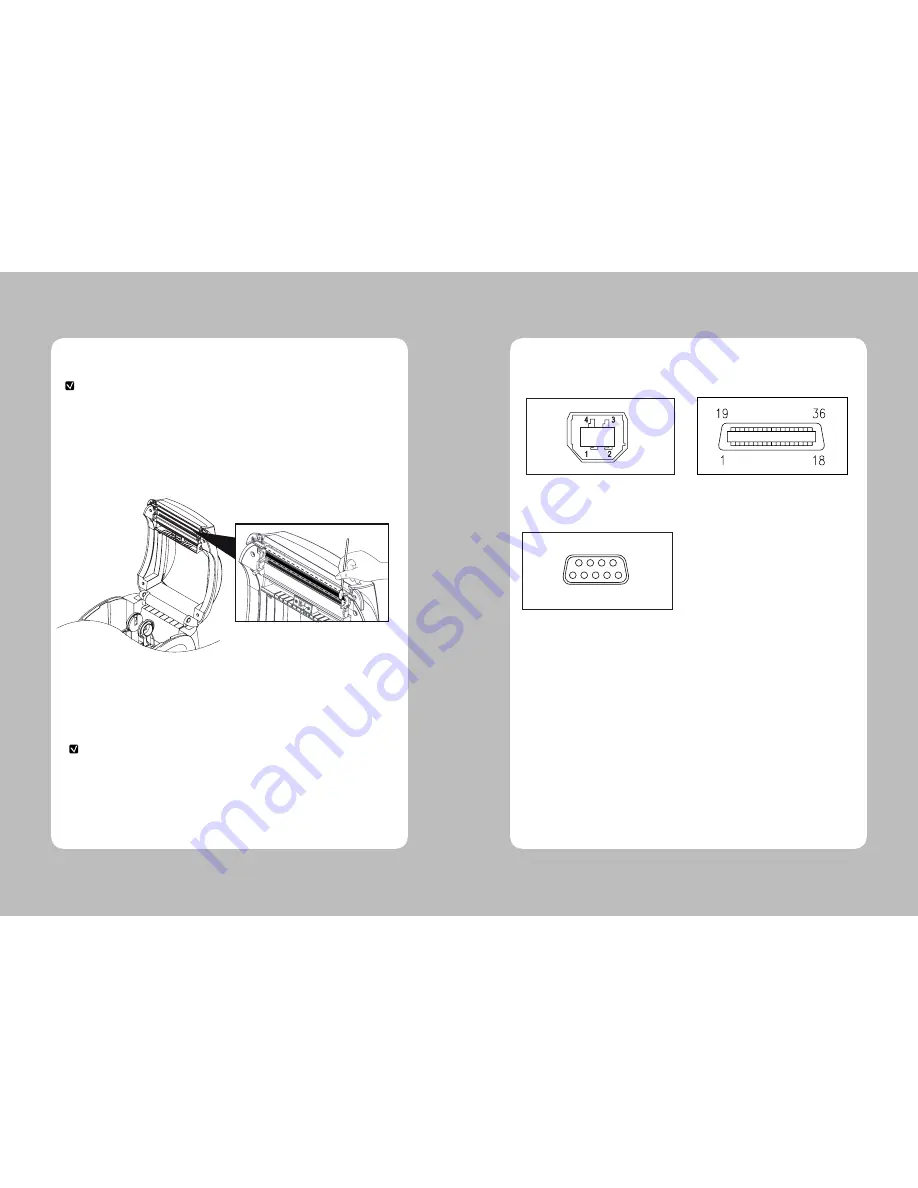

12. Printer cleaning

If the interior of the printer is dusty, printing quality can lowered.

In such a case, follow the instructions below to clean up the printer.

1. Make sure to turn the printer power off prior to cleaning

2. Regarding print head cleaning, as the print head sets very hot during printing, turn off the

printer power and wait approximately 10 minute before commencement.

3. When cleaning the print head, take care not to touch the heated portion of the print head.

The print head subject to be damaged by static electricity.

4. Take care not to allow the print head to become scratched and /or damaged in any way.

Preventing Overheating

To prevent the motor from overheating, continuous driving of the printer should be 1.5 m

or less in print length. Set the pause time for 30 seconds or more after driving the printer.

NOTE

1. Use an applicator swab moistened with an alcohol solution to clean the print head and

remove any dusts.

2. Once the cleaning is completed, insert paper roll into the printer few minutes later and

close the printer cover.

13. Connector

Interface Connectors

<USB “ B “ TYPE>

<Centronics Parallel>

Standard

<9 Pin Serial>