23

Gilian

®

LAB & FIELD CALIBRATOR SYSTEM

Sensidyne Document No. F-PRO-1260 (Rev C)

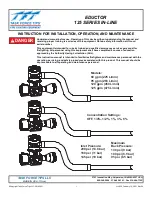

4.2

FLOWTUBE CLEANING

Refer to Figure 1 & 2. It is advisable every six months to

clean the flow meters of any debris which may have ac-

cumulated during that usage period. This procedure

covers the removal of the flow meters from the panel,

cleaning of the individual flow meters and reinstallation

of the panel. The procedure which is given is for a

three-tube panel.

1)

Remove the four sheet metal screws, (#14 & 20),

holding the upper/lower manifold blocks.

2)

Remove additional four sheet metal screws, (#21),

holding the rotameter sheet metal assembly. These

are the screws just outside of the clear glass protec-

tion window.

3)

Remove the three pieces of interconnecting tubing,

(#16), from the upper manifold block.

4)

Pry the upper manifold block containing the tube

coupling, (#19), from the flowtubes.

5)

After removing these tubes, all three can be slid

down through the sheet metal flowtube housing.

Each individual flowtube can then be separated

from the lower manifold.

6)

Clean the flowtube, using lab grade alcohol in a sy-

ringe through the bottom.

7)

After cleaning, blow dry with compressed air or air

dry.

8)

Check the ball for freeness in the bore and

flowtube, then adjust the upper and lower

flowtube stops to prevent ball sticking in the tube.

9)

Clean the upper and lower manifolds using alcohol

and blow dry.

10) Re-assemble the manifold as follows. Place the tu-

bular rubber boots, (#23), on to the bore of each

flowtube, approximately 1/2” and then insert the

bottom of each tube into the lower manifold block,

making sure the measurement scale faces forward.

The boss of the manifold should also face forward.

11) Re-install all three flowtubes in the housing.

12) Install the three tubes (#11, 12 & 13) onto the top

of the flow meter and insert the upper manifold

block, bosses facing out from the back of the

panel.

13) Re-install the now complete assembly through the

panel face and replace all screws.

14) Re-attach the three tube couplings (#16), to the up-

per manifold. Leakage check the assembly before

using.