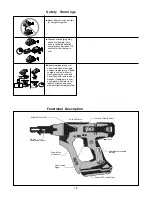

Tool Operation

13

Changing the bit

l

Due to wear or damage, the

bit will need to be replaced

periodically or when changing

between drive types.

l

(1) Maintain forward pressure

on tool. (2) Pull the trigger

to start motor. Continue

operation until screw is

completely

disengaged.

l

Depress nose piece while

inserting bit into screw.

Forward Reverse

Operation

l

To operate in reverse,

remove the screw strip and

push the black reverse button

l

Test drive one screw before

finalizing the depth to ensure

appropriate countersink.

l

This tool has a depth-sensing

clutch. When the screw

is countersunk to the pre-

set depth, it automatically

disengages and makes a click

or racheting sound. This is

normal and signals completion

of the drive.

l

When the battery is low or

the drive requires too much

torque, the tool may stall at

the bottom of the drive (before

the clutch can disengage).

Continuous operation in this

manner can cause over-

heating and permanent

damage.

l

If the fastener to be removed

was driven to the proper

depth, it will be necessary

to adjust the depth of drive

deeper (see depth of drive

adjustment page 12) before

the clutch will engage in

reverse.