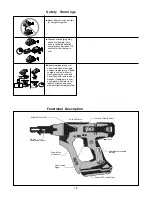

Tool Operation

14

l

Remove fasteners from the

tool. (1) Slide bit release

button to rear. (2) Tilt tool

forward and pulse trigger.

Bit will fall out.

l

(1) Hold tool upright. Insert

the new bit into the slide

body. (2) Slide bit release

button to rear. (3) Pulse tool

and release button when bit

drops into place.

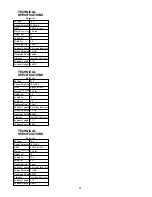

1

1-1/2

1-5/8

1-1/4

1-3/4

2

1

1-1/2

1-5/8

1-1/4

1-3/4

2

1

1-1/2

1-5/8

1-1/4

1-3/4

2

1

1-1/2

1-5/8

1-1/4

1-3/4

2

Changing the nosepiece

l

Remove battery before

changing the nosepiece.

l

Remove retention screw.

(a coin can be used if a

screwdriver is not available)

l

Set the nosepiece on the

longest setting possible.

(see adjusting fastener

length pg. 11)

l

Depress the screw selector

pin until it is completely

depressed. It will be necessary

to use a screw or thin object to

depress to this depth

l

While holding the pin in this

position, slide the nosepiece

forward and off of the slide

body

l

Install the new nosepiece

l

Replace the nosepiece

retention screw ensuring it is

seated snug against the slide

body

Adjusting belt hook

l

Remove the belt hook thumb

screw until the locking plate

can be removed

l

Slide the belt hook out to the

desired position, replace the

locking plate, then re-install

the thumb screw

Moving belt hook to

alternate side

l

Remove the thumb screw,

locking plate, threaded plate

and belt hook

l

Insert the threaded plate

on the opposite side of tool

and re-install the hook at the

desired position using locking

plate and thumb screw

1

1-1/2

1-5/8

1-1/4

1-3/4

2

1

1-1/2

1-5/8

1-1/4

1-3/4

2