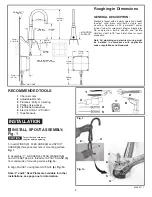

Fig. 2

3-3/4"

(96mm)

2-3/4"

(71mm)

3"

(76mm)

6

4

5

2

2

3

1

1

MOUNTING

BRACKET

SUPPLIES

WASTE

ENCLOSURE

MOUNTING

HOLES

3

1524mm

(60)

20"

(500mm)

MOUNTING

BRACKET

NOTE: If using Mixing Valve (optional) See Sheet

#M968808 for installation instructions.

1.

For installation on ICU Sink mount ENCLOSURE

(1)

on MOUNTING BRACKET

(2)

with SCREWS

(3)

.

2.

For all other sinks or countertops determine location

of ENCLOSURE

(1)

. It must be located within the 14"

(356mm) by 21" (533mm) shaded area shown in

Figure 2

in order for electrical connections from the

spout assembly to be completed.

NOTE: ENCLOSURE SUPPLY HOSE is 20". Distance

between wall supply and ENCLOSURE (1) must be

taken into consideration.

3.

Remove 4 screws from COVER

(6)

and pull off

COVER

(6)

. Hold the ENCLOSURE

(1)

in desired

location and mark the four mounting hole locations as

shown.

Fig. 2.

4.

The ENCLOSURE

(1)

works best if secured to a wall

stud or cross brace within the wall, using the SCREWS

(4)

supplied. If the ENCLOSURE

(1)

is to be installed on

a tile or plaster wall the ANCHORS

(5)

and SCREWS

(4)

should be used.

Fig. 2.

5.

For installations on drywall or tiled walls;

use

ANCHORS

(5)

and SCREWS

(4)

for securing

ENCLOSURE

(1)

to finished wall. Drill four 1/4" dia.

holes a minimum of 1-3/4" deep. Insert the four

ANCHORS

(5)

flush with face of the finished wall.

Align the ENCLOSURE

(1)

and Install the MOUNTING

SCREWS

(4)

. Tighten to secure ENCLOSURE

(1)

to

mounting surface.

NOTE. The illustration shows the ICU FAUCET mounted

on the American Standard ICU Sink. Faucet can be

installed on almost any sink or countertop. For Faucet

installation on the American Standard ICU Sink, see

instruction sheet No. 7301793-100 (ICU Sink System)

supplied with Sink for more detailed information.

MOUNT ENCLOSURE; Fig. 2

2

1.

Connect SUPPLY NUT

(1)

from spout assembly to

nipple on top of ENCLOSURE

(2)

. Tighten with adjustable

wrench to make a water tight connection.

Fig. 3.

NOTE; If using the optional Mixing Valve See Sheet

#M968808 for installation instructions.

CONNECT SPOUT HOSE TO

ENCLOSURE; Fig. 3

CONNECT WATER SUPPLY TO

ENCLOSURE AND WALL SUPPLY;

Fig. 4

3

Fig. 3

4

1

2

1

3

3

Fig. 4

2

1.

Insert FIBER WASHER

(4)

into SUPPLY NUT

(1)

on

ENCLOSURE

(2)

.

2.

Connect SUPPLY NUT

(1)

on ENCLOSURE

(2)

to

FLEXIBLE SUPPLY HOSE

(3)

. Tighten to make a water tight

connection. Use two wrenches to tighten if necessary.

Fig. 4.

3.

Connect FLEXIBLE SUPPLY

(3)

directly to wall supply.

Connection on FLEXIBLE SUPPLY

(3)

is 3/8" compression.

Use adjustable wrench to tighten connection. Do not over

tighten.

Fig. 4a.

Note:

FLEXIBLE SUPPLY

(3)

measures 20" from the bottom

of the ENCLOSURE

(1)

base. If additional supply length is

required, installer must purchase parts separately.

Important:

If FLEXIBLE SUPPLY

(3)

is too long, loop to avoid kinking.

COLD WATER OR

TEMPERED

WALL SUPPLY

OTHER SINK

INSTALLATION

Fig. 4a

4

M 9 6 5 2 7 1

14"

(356mm)

21"

(533mm)

DO NOT USE PIPE

SEALANT ON THREADS

4" ELECTRICAL BOX

OR EQUIVALENT BY

OTHERS