SECO-LARM

ELECTROMAGNETIC LOCK

SECO-LARM U.S.A., Inc.

5

7.

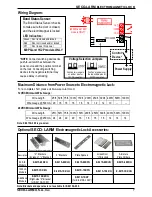

Put a rubber washer between the two metal washers,

and place them over the armature screw between

the armature plate and the door. This allows the

plate to pivot around the screw to compensate for

door misalignment.

9

.

Screw the two short self-tapping screws through the mounting plate’s slotted holes, but do not over-tighten them.

Keeping them loose will allow for adjustment of the plate left or right so that the mounting plate and the armature

plate form a 90-degree angle. See the diagram below.

8.

Tighten the armature screw enough so that the

armature plate can withstand a break-in attempt, but

loose enough so that the armature plate can pivot

slightly. Make sure the anti-spin guide pins are in the

two guide pin holes.

Mounting Plate

Armature Plate

90

The rubber washer will be

sandwiched between the

two metal washers.

Armature

screw

Guide pins

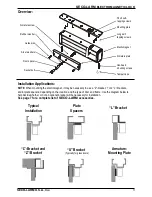

6.

Depending on the type of door being protected, drill holes according to the diagrams below:

Hollow Metal Door

Solid Core Door

Reinforced Door

1/4” (6.8mm) for M8x1.25 thread

Drill a 5/16” (8mm) dia. hole through the

armature-plate side of the door for the

armature screw. Then drill a 5/8” (16mm)

dia. hole for sexnut screw on the

opposite side of the door.

Drill an 5/16” (8mm) dia. hole on the

door for the armature screw, and drill a

1/2” (12.7mm) dia. and 1” (25mm) deep

hole for the sexnut screw.

Drill a 1/4” (6.8mm)

dia. and 1” (25mm)

deep hole, tap for

M8x1.25 thread.

Tip:

Use a thread-locking compound

on the armature screw to ensure

a long-lasting installation.

Metal

washers

5/8” (16mm)

5/16” (8mm)

1/2” (12 .7mm)

5/16” (8mm)

300-lb and 600-lb

mounting plate

300-lb mounting plate