CT2X INSTRUCTIONS

Seametrics • 253.872.0284

Page 10 seametrics.com

INSTALLATION

Installing the Sensor

• Lower the sensor to the desired depth

1

.

• Fasten the cable to the well head using a weather

proof strain-relief system. When securing a vented

cable, make sure not to pinch the cable too tightly

or the vent tube inside the cable jacket may be

sealed off.

• Take a measurement to insure the sensor is not

installed below its maximum range.

Be sure the supplied cap is securely placed on the weather-

resistant connector at the top of the cable. Do not install

such that the connector might become submerged with

changing weather conditions. The connector can withstand

incidental splashing but is not designed to be submerged.

If the sensor has the vented pressure option, install the

sensor so that the desiccant tube will not flood or lie in

water.

The sensor can be installed in any position; however, when

it leaves the factory it is tested in the vertical position.

Strapping the sensor body with tie wraps or tape will not

hurt it. If the sensor is being installed in a fluid environment

other than water, be sure to check the compatibility of the

fluid with the wetted parts of the sensor.

Desiccant Use

On sensors with a vented pressure option, a desiccant tube

prevents moisture in the air from being sucked into the

vent tube, which can cause erratic readings and sensor

damage.

The desiccant tube is filled with blue silica gel beads. A

locking barb and a hydrophobic water filter are attached to

the end of the desiccant tube. This filter prolongs the life of

the desiccant as much as three times over a desiccant tube

without the filter.

Install the sensor so that the desiccant tube and cable

connector will not flood or lie in water.

The desiccant is a bright blue color when active and dry. See

Maintenance section for care and changing of desiccant.

1 If your CT2X has the pressure option, then the maximum installation

depth depends on the range of the sensor. One (1) PSI is equal to

approximately 2.31 feet of water. If you have a 5 PSI sensor, the range

is 11.55 feet of water and the sensor should not be installed at a depth

below 11.55 feet. If the sensor is installed below its maximum range,

damage may result to the sensor and the output reading will not be

correct.

Grounding Issues

It is commonly known that when using electronic

equipment, both personnel and equipment need to be

protected from high power spikes that may be caused by

lightning, power line surges, or faulty equipment. Without

a proper grounding system, a power spike will find the

path of least resistance to earth ground—whether that

path is through sensitive electronic equipment or the

person operating the equipment. In order to ensure safety

and prevent equipment damage, a grounding system must

be used to provide a low resistance path to ground.

When using several pieces of interconnected equipment,

each of which may have its own ground, problems with

noise, signal interference, and erroneous readings may be

noted. This is caused by a condition known as a Ground

Loop. Because of natural resistance in the earth between

the grounding points, current can flow between the points,

creating an unexpected voltage difference and resulting

erroneous readings.

The single most important step in minimizing a ground loop

is to tie all equipment (sensors, dataloggers, external power

sources, and any other associated equipment) to a single

common grounding point.

Seametrics recommends

connecting the shield to ground at the connector end.

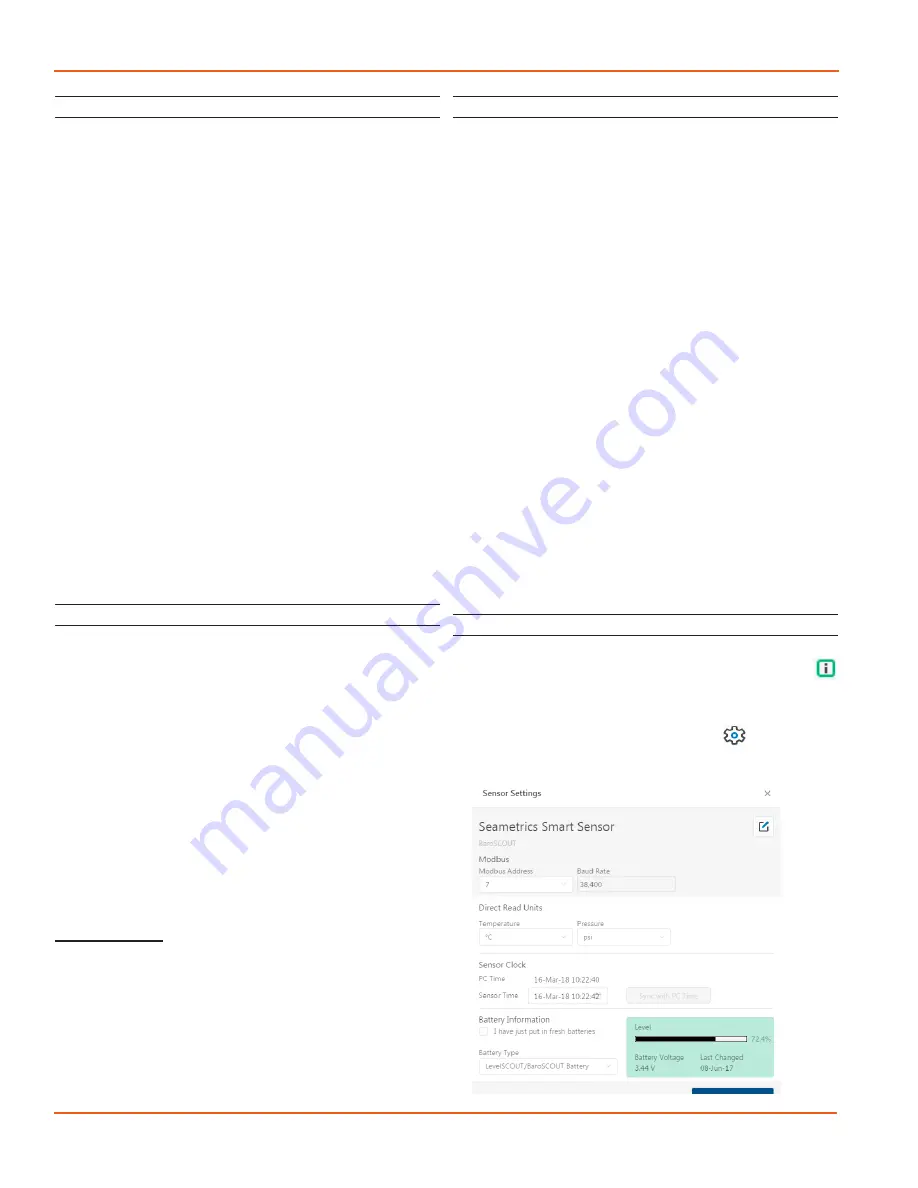

Sensor Settings

Once connected you’ll see the Sensor screen appear and

display the connected sensor(s) details. Mousing over

icons will provide tool-tips, mouse over to view sensor

firmware and serial number details.

To change general sensor settings click in the sensor

screen. This allows you to change the following: