- 24 -

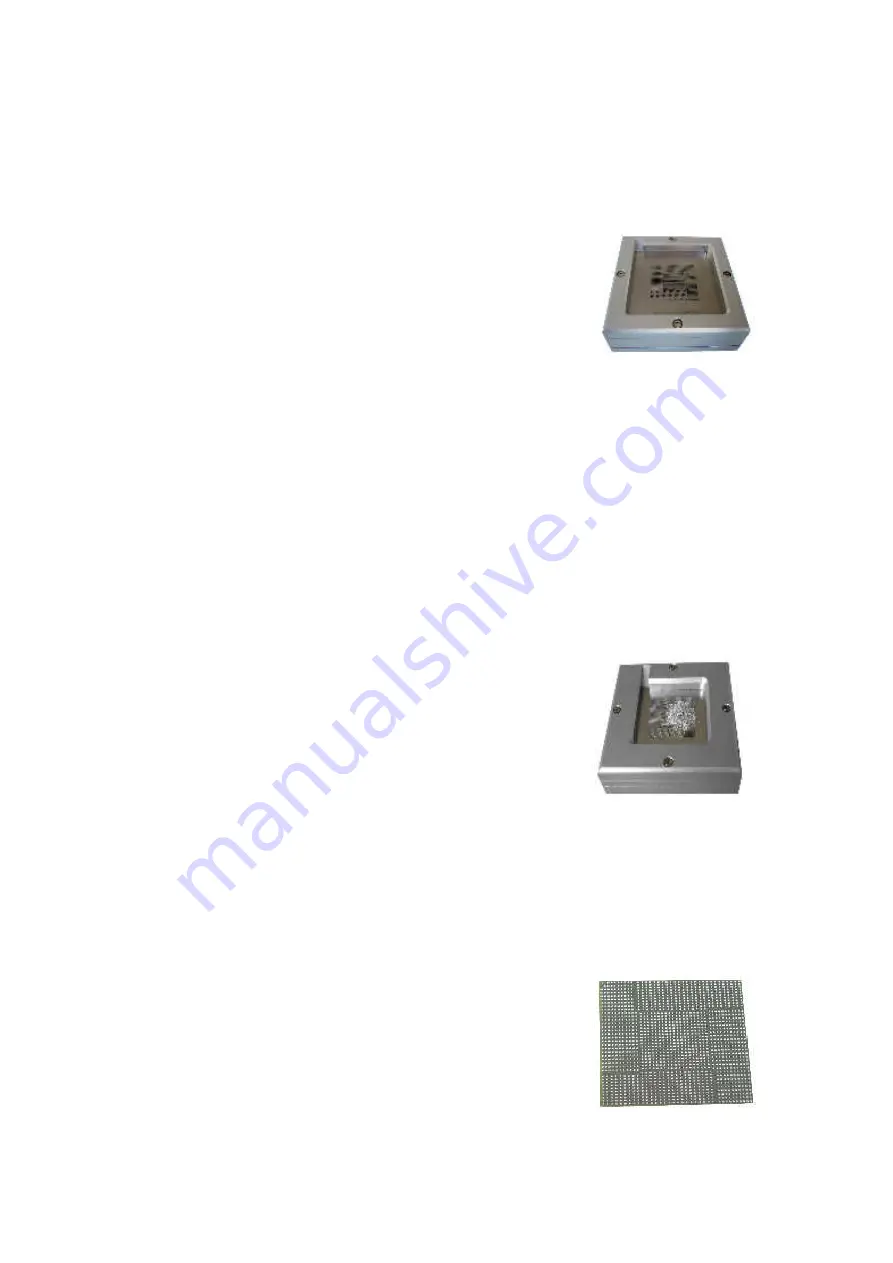

of the reballing kit.

2

、

Select the appropriate steel mesh according to chip type. Fix the steel

mesh to the ceiling cover and tighten it with 4

M3 screws, covered with lid. Adjust 4 Jimmy

on the base to meet the suitable height

required.

3

、

Observe the hole on steel mesh which should be completely coincide

with the solder holes on BGA. If not coincide, we must remove the

cap to reposition to ensure steel mesh holes aligned with the chip,

and then lock the four screws.

4

、

Locking two no spring fixed slide, remove the BGA chip and coated

with a thin layer of solder flux, card the chip

into the base again, covered with lid(make sure

the right direction).

5

、

Put into solder ball, clench hands and gently

swaying reballing station to ensure the solder ball completely filled

in the holes and pour out extra solder balls.

6

、

Place the reballing station on the flat location; Remove the lid,

carefully scored BGA chips. Observe the chip,

if individual solder balls are not in the hole

rightly, please correct it with forceps.