NOTE:

It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT:

no liability is accepted for incorrect use of this product.

WARRANTY:

Guarantee is 12 months from purchase date, proof of which will be required for any claim.

Sole uK distributor, Sealey Group.

K

empson Way, Suffolk Business Park,

B

ury St. edmunds, Suffolk.

IP32 7Ar

www.sealey.co.uk

01284 757500

01284 703534

Web

Environmental Protection

recycle unwanted materials instead of disposing of them as waste. All tools, accessories and packaging should be sorted,

taken to a recycling centre and disposed of in a manner which is compatible with the environment.

WEEE Regulations

d

ispose of this product at the end of its working life in compliance with the EU Directive on Waste Electrical and Electronic

Equipment (WEEE). When the product is no longer required, it must be disposed of in an environmentally protective way.

Contact your local solid waste authority for recycling information.

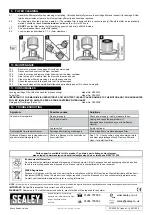

9. FILTER CLEANING

f

9.1.

Handle the filter carefully when cleaning or installing. unlock and carefully remove the cartridge filter and inspect it for damage. A filter

that has small holes or tears in it will not perform efficiently and should be replaced.

9.2.

to clean a dry filter, tap it inside a waste bin. (the cartridge filter is designed for dry vacuuming only). Should the filter be

inadvertently

wetted it should be rinsed

from the inside

and allowed to air dry for 24 hours.

8

DO NOT

use the filter wet as the filter will clog quickly and be very difficult to clean.

9.3.

Fit a new/cleaned filter over the filter basket

9.4.

Lock in place as described in 7.1.2. (0mm clearance).

10. MAINTENANCE

10.1.

ensure the machine is unplugged from the power supply.

10.2.

disconnect the hose from the drum container.

10.3.

undo the clasps and remove motor housing from the drum container.

10.4.

Clear out any dirt or debris from the drum container and hoses.

10.5.

Clean the foam filter by washing it in a mild soapy solution.

10.6.

Check the power cable to make sure that it is not damaged.

10.7.

Frequently clean out the safety float slides and periodically inspect it to check its integrity.

11. CONSUMAbLES

Locking Cartridge Filter (must be used for dry vacuuming). . . . . . . . . . . . . . . . . model no: dFS35CF

Foam Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . model no: dFS35FF

IMPORTANT! IF THE MACHINE IS USED WITHOUT A FILTER FITTED THIS MAY CAUSE DAMAGE TO THE MOTOR AND YOUR GUARANTEE

WILL bE INVALIDATED. ALWAYS KEEP A SPARE CARTRIDGE FILTER HANDY.

Category M Dust Bags (Pack of 5)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Model No: DFS35PB

12. TROUbLESHOOTING

fig.7

Symptom

Possible causes

Solutions

Vacuum will not operate

no power supply

Check power supply - cable, breakers, fuses.

Faulty power cable

unplug and check the power cable. If

damaged have it replaced by your local Sealey

stockist.

Container full

empty container

dust expelled from the motor cover

Cartridge filter missing or damaged

Fit cartridge filter or replace damaged filter

Reduced efficiency and increased motor/

speed vibration/orange light (C)

there is a blockage in the nozzle/hose/

drum inlet/ filter.

See 7.1.4.. Check nozzle, hose and container inlets

and clear any blockages found. Remove filter and

clean it or install new filter.

PC35230V | Issue 3 (I) 05/10/16

Original Language Version

© Jack Sealey Limited

Parts support is available for this product. To obtain a parts listing and/or diagram,

please log on to www.sealey.co.uk, email [email protected] or telephone 01284 757500.