14

S E T - U P A N D O P E R A T I O N

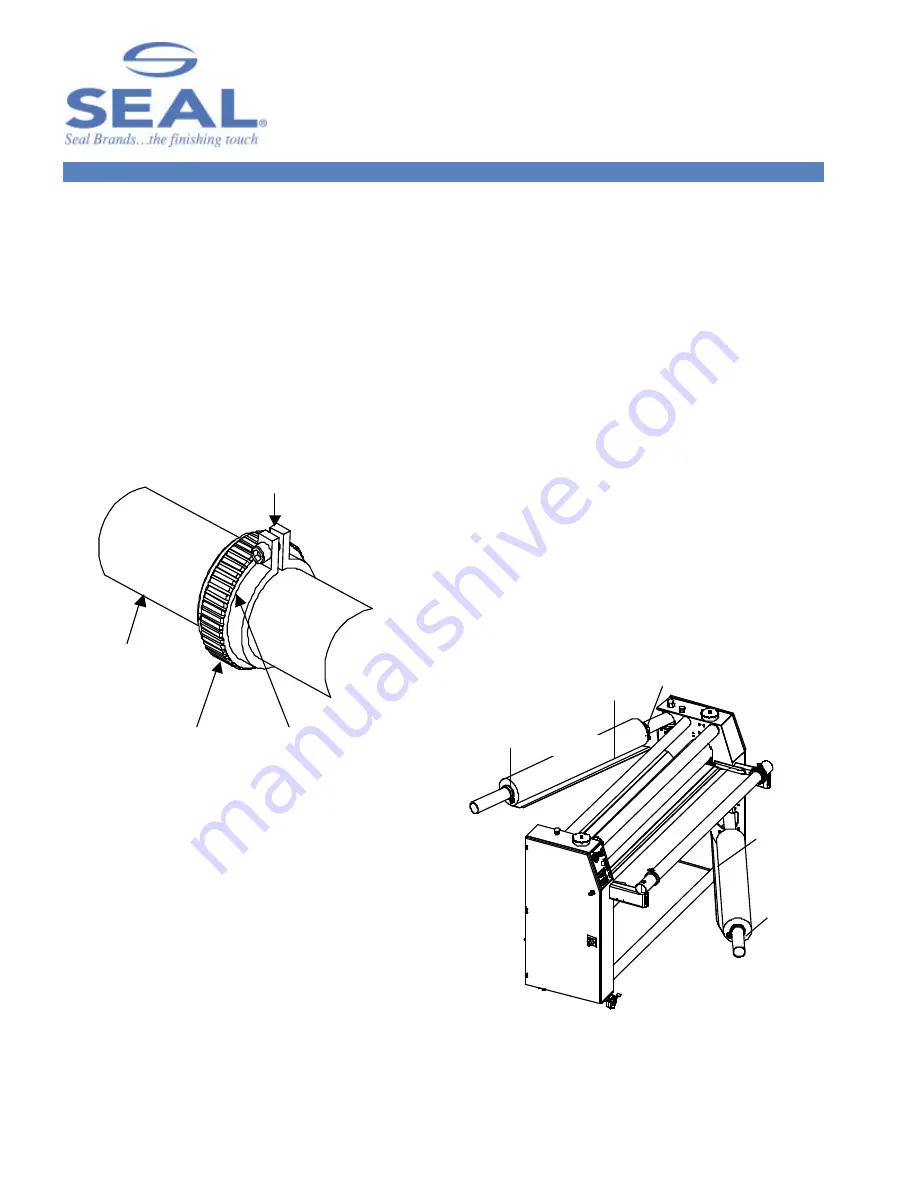

SETTING THE UNWIND BRAKE TENSION

IMPORTANT! The brake tension greatly

affects the smooth flow of the laminating film.

•

Turning the unwind brake in a counter-clockwise

direction increases the braking tension applied on

the laminate.

•

Turning the unwind brake in a clockwise direction

decreases the braking tension.

•

The best setting for the unwind brake tension is

determined by the materials you are using and is

learned through experience.

Figure 6. Unwind Brake

LOADING A ROLL OF MATERIAL

IMPORTANT! Make sure to fully release brake

tension whenever changing a roll of film.

•

Swing out the desired unwind shaft towards you

and use the 5/16 T-handle to loosen the setscrew

and remove the Lock Collar from the unwind shaft.

•

Slide a roll of material onto the unwind shaft and

replace the lock collar.

IMPORTANT! Make certain that you place the

roll of film on the unwind shaft so that the

material will feed with the adhesive side facing

away from the rollers.

•

Press the unwind shaft firmly back into the receiver

to prevent tension and tracking problems.

•

Center the films on the unwind shafts. Measure the

distance from the face of the cabinet and the film

edges (not the cores) and adjust until they are equal.

IMPORTANT! The position of all films,

boards, rolls of media and cardboard cores for

wind-ups must be set central in the laminator to

ensure optimum quality and correct tracking.

•

Adjust the brakes and lock collars flush against the

roll ends and tighten the setscrews.

IMPORTANT! Do not over-tighten the

setscrews to prevent stripping the threads.

Figure 7. Loading Roll of Material

Unwind

Shaft film

goes on this

side of brake

Tension ring

Brake tension is fully

released when the tension

ring and collar gap is closed

Brake Collar

Adhesive Side

Adhesive Side

Brake Side

Lock Collar

Lock Collar