Jumper 25

Instruction Man u al

4

5.

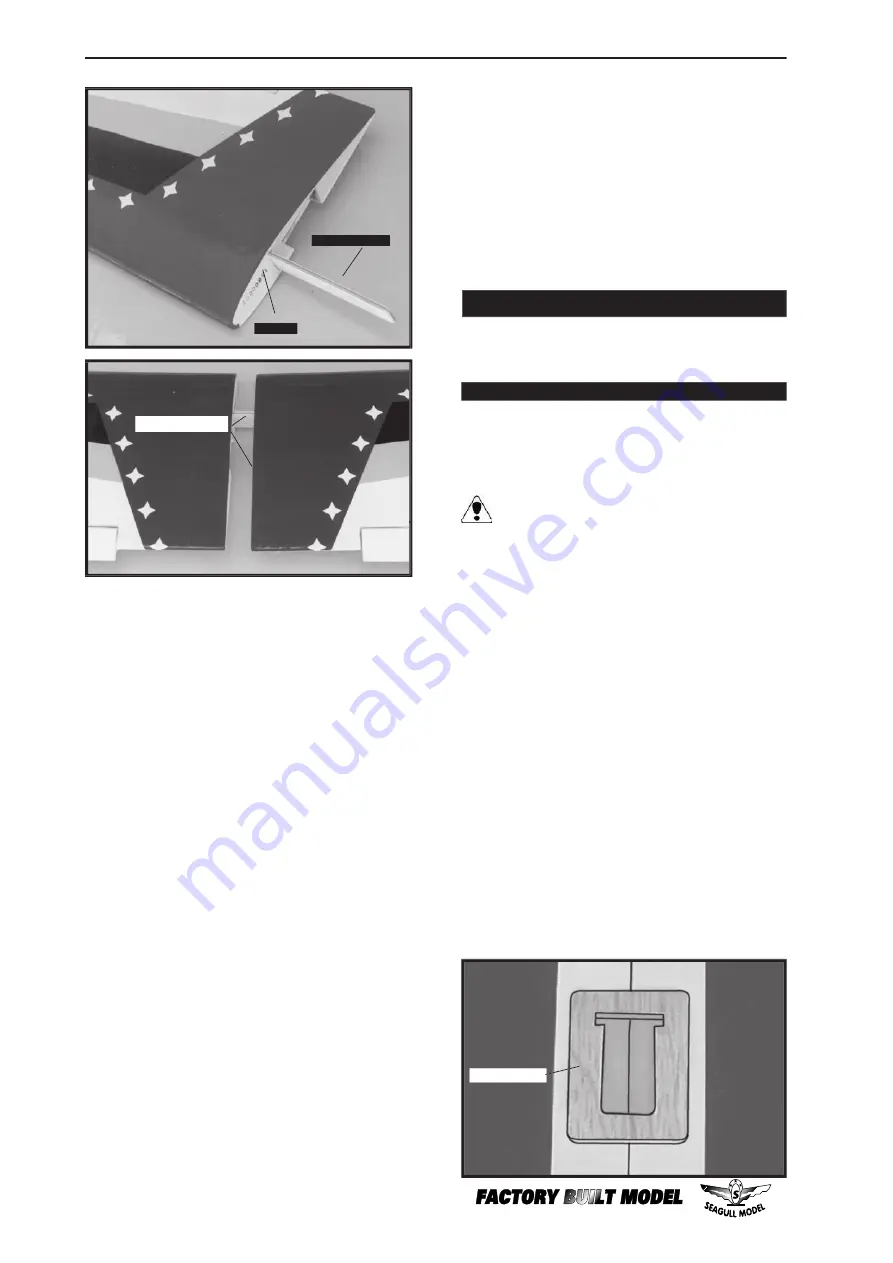

Once the epoxy has cured, trial fi t

both wing halves together. The cen tre

ribs should fi t together fl ush with no

gaps. If gaps do exist, use 220 grit

sandpaper and sand down the high

spots on the root ribs and the wing

joiner until a proper fi t is achieved. The

correct amount of dihedral is ready-

built into the wings. With one wing half

laid fl at on the table, the other wing

tip should be ap prox i mate ly 8cm off

the table surface. If this needs to be

adjusted, you may do so by sanding

small amounts from the cen tre ribs

or dihedral brace.

6.

Carefully apply masking tape around

the top and bottom edge of the root

rib of each wing half to protect them

from damage caused by epoxy.

7.

Mix a generous amount of 30 minute

epoxy. Coat the exposed half of the

dihedral brace, and the remaining

wing joiner box and both root ribs

with epoxy. Slide the two wing halves

to geth er and carefully align them at

the leading and trailing edges. Wipe

away any excess epoxy using paper

tow els. Use mask ing tape wrapped

around the centre section to hold

the halves in place until the epoxy

cures.

PARTS REQUIRED

SERVO INSTALLATION

INSTALLING THE AILERON SERVO MOUNT

{1} Plywood Aileron Servo Mount

1) Install the rubber grommets and brass

collets onto the aileron servo. Test fi t the ser vo

into the ai le ron servo mount.

Because the size of servos differ, you

may need to adjust the size of the precut

opening in the mount. The notch in the

sides of the mount allow the servo lead to

pass through.

2) Remove the aileron servo. Place the

mount onto the wing, aligning the cutout in the

mount with the cutout in the wing. The two

notches in the mount should face the leading

edge of the wing.

3)

While holding the servo mount fi rmly

in place, trace around it using a pen.

4) Remove the mount, and using a

mod el ing knife, carefully remove the covering

from inside the outline you drew.

5) Using Kwik Bond 5 Minute Epoxy,

glue the servo mount into place. Remove

any ex cess epoxy using a paper towel and

rubbing alcohol. Use pieces of masking tape

to hold the tray in place until the ep oxy fully

cures.

8.

When the epoxy has cured, care ful ly

remove the masking tape from the

wing.

9.

Peel off the backing from the self ad-

he sive covering strip. Apply the strip to

the centre section of the wing starting

from the bottom trailing edge. Wrap

the strip all the way around the wing

until it meets the trailing edge again.

Trim off any excess strip.