Aqua Whisper DX Modular 450-1800

Page 3-23

Pre-installa

tion

hose. Also used for a manual fresh water flush if

the Automatic Fresh Water Flush System is not

installed. The Rinse Clean Valves are available on

single valve mounting plates or on double valve

mounting plate.

7.

Rinse Clean Outlet Valve *** used in conjunction

with and identical to the Rinse Clean Inlet Valve

simplifies the storage and cleaning procedures by

allowing the operator to turn a valve rather than

disconnect a hose.

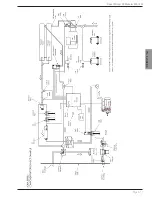

ELECTRONIC SECTION

The Electronic Section measures water quality, controls

the direction of Product Water flow, Starts and Stops the

pumps, and contains the central electrical connection

point of the system. It also ensures only potable Product

Water passes into the Product Water Storage Tank.

1.

System Touch Panel is where all system functions

are accessed by touching the user friendly

intuitive screen and where all operating conditions

are monitored.

2.

Electrical Control Box contains all electrical and

electronic components that control the system.

3.

Remote Control Touch Panel *** allows for remote

control, operation, and monitoring of the system.

4.

Soft Start *** The soft start, used only in AC Single

Phase systems, reduces the initial startup amperes

required to start the High Pressure Pump Motor

and in turn allows a smaller sized KW generator to

start the system. Starting amperage is reduced by

40% with the Soft Start installed.

Not Numbered:

Fresh Water Tank Low Level Switch ** owner/installer

supplied provides an optional feature to the System

Control Logic that works in conjunction with the

Automatic Fresh Water Flush option.

When installed and connected to the Main Printed Circuit

Board, the Fresh Water Tank Low Level Switch must be

connected as a N.O. (Normally Open) 1PST (One Pole

Single Throw) switch.

When the Fresh Water Tank is empty the switch is Open.

As water rises a few inches in the tank the switch Closes.

This informs the System Control Logic that there is

sufficient Fresh Water to perform the Automatic Fresh

Water Flush Cycle.

2.

Fresh Water Pressure Pump** delivers fresh water

throughout the boat, or home. In order to provide

the required flow of water to the System during

the Fresh Water Flush cycle, this pump must

deliver up to 1 U.S. Gallons (3.8 Liters) Per Minute

at 25 to 60 PSI (172 to 414 kPa).

3.

Air Entrainment Tank** (accumulator) is sometimes

installed into the boat or home’s fresh water line to

eliminate pulsations from and reduce demand on

the Fresh Water Pressure Pump. This tank stores

pressurized fresh water for delivery to the boat or

home’s fresh water piping.

FRESH WATER FLUSH SECTION

The Fresh Water Flush Section includes a Carbon

Filter and an Automatic Motor Actuated Ball Valve that

automatically flushes the system with fresh water. This

process is automatic at each shut down of the system

and repeats automatically every preset number of days.

Fresh Water Flushing replaces the seawater in the

system with less corrosive fresh water, and this also

reduces the biological growth and subsequent decay that

naturally occur if the sea water is not flushed from the

system with fresh water.

1.

Fresh Water Flush 2-way solenoid valve

***automatically actuates at system shut down

and every preset number of days there after to

flush the system with fresh water.

2.

Fresh Water Flush Check Valve *** prevents feed

water from entering the fresh water line.

3.

Fresh Water Flush Charcoal Filter *** removes

chlorine, if present, in the fresh water prior to

flowing through the R.O. Membrane Element.

4.

Fresh Water Flush Check Valve *** routs the fresh

water through the system.

5.

Cleaning Bucket ** can be any non ferrous

container capable of holding at least 10 U.S.

Gallons (37.8 Liters) of water. This container is

used during the R.O. Membrane Element cleaning,

storing, or winterizing process.

6.

Rinse Clean Inlet Valve *** These Optional Valves

are mounted separately on singular individual

plates or together on a double plate.

The Rinse Clean Inlet Valve is used in conjunction

with the Rinse Clean Outlet Valve simplifies the

storage and cleaning procedures by allowing the

operator to turn a valve rather than disconnect a

Summary of Contents for Aqua Whisper DX 1400-2

Page 2: ......

Page 3: ...Aqua Whisper DX Modular 450 1800 Owner s Manual...

Page 4: ......

Page 11: ...Introduction Aqua Whisper DX Modular 450 1800 Section 1 INTRODUCTION...

Page 12: ...Introduction...

Page 15: ...Description Aqua Whisper DX Modular 450 1800 Section 2 SYSTEM DESCRIPTION...

Page 16: ...Description...

Page 21: ...Aqua Whisper DX Modular 450 1800 Page 2 5 Description COMPLIANCE CERTIFICATES...

Page 23: ...Aqua Whisper DX Modular 450 1800 Page 2 7 Description...

Page 25: ...Aqua Whisper DX Modular 450 1800 Page 2 9 Description...

Page 30: ...Aqua Whisper DX Modular 450 1800 Page 2 14 Description OPTIONAL ACCESSORIES...

Page 38: ...Aqua Whisper DX Modular 450 1800 Page 2 22 Description This page is intentionally left blank...

Page 39: ...Aqua Whisper DX Compact 450 1800 Section 3 PRE INSTALLATION NOTES Pre installation...

Page 40: ...Pre installation...

Page 56: ...Aqua Whisper DX Modular 450 1800 Page 3 16 Pre installation...

Page 57: ...Aqua Whisper DX Modular 450 1800 Page 3 17 Pre installation...

Page 65: ...Aqua Matic Compact 450 1800 Section 4 ELECTRICAL INFORMATION Electrical...

Page 66: ...Electrical...

Page 75: ...Aqua Whisper DX Modular 450 1800 Page 4 9 Electrical Electrical Motor Wiring Three Phase...

Page 80: ...Electrical...

Page 81: ...Installation Aqua Whisper DX Modular 450 1800 Section 5 INSTALLATION REQUIREMENTS...

Page 82: ...Installation...

Page 94: ...Aqua Whisper DX Modular 450 1800 Page 5 12 Installation...

Page 95: ...Commissioning Aqua Whisper DX Modular 450 1800 Section 6 COMMISSIONING...

Page 96: ...Commissioning...

Page 106: ...Aqua Whisper DX Modular 450 1800 Page 6 10 Commissioning...

Page 107: ...Operation Aqua Whisper DX Modular 450 1800 Section 7 OPERATION...

Page 108: ...Operation...

Page 120: ...Aqua Whisper DX Modular 450 1800 Page 7 12 Operation...

Page 122: ...Aqua Whisper DX Modular 450 1800 Page 7 14 Operation...

Page 123: ...Aqua Whisper DX Compact 450 1800 Section 8 MAINTENANCE AND REPAIR Maintenance...

Page 124: ...Maintenance...

Page 145: ...Troubelshooting Troubelshooting Aqua Whisper DX Modular 450 1800 Section 9 TROUBLESHOOTING...

Page 146: ...Troubelshooting...

Page 167: ...Parts View Aqua Whisper DX Modular 450 1800 Section 10 EXPLODED PARTS VIEW...

Page 168: ...Parts View...

Page 183: ...Aqua Whisper DX Modular 450 1800 Page 10 15 Parts View...

Page 191: ...Aqua Whisper DX Modular 450 1800 Page 10 23 Parts View...

Page 217: ...Sheet 11 3 Aqua Whisper DX Electrical Wiring Diagram 110 120 VAC 50 60 HZ Single Phase...

Page 219: ...Sheet 11 5 Aqua Whisper DX Electrical Wiring Diagram 208 240 VAC 50 60 HZ Single Phase...

Page 221: ...Sheet 11 7 Aqua Whisper DX Electrical Wiring Diagram 200 240 VAC 50 60 HZ Three Phase...

Page 223: ...Sheet 11 9 Aqua Whisper DX Electrical Wiring Diagram 380 460 VAC 50 60 HZ Three Phase...

Page 225: ......