Aqua Whisper DX Modular 450-1800

Page 3-20

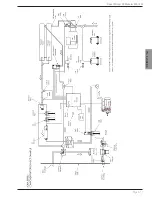

Pre-installa

tion

CAUTION

: A flush inlet thru-hull fitting

will cause a vacuum as the boat is under

way, and will cause loss of feed water

flow, cavitation of the feed pump and

high pressure pump resulting in continual

system shut down.

CAUTION

: If the thru-hull fitting is placed

in a position on the underside of the

hull that allows air to continually enter

the thru-hull fitting, it will cause the

system to continually shut down due to

loss of feed water.

NOTE

: The resulting failure of the system

to remain in operation is attributed to

improper installation, is the liability of the

installer, and is not covered by the Sea

Recovery warranty.

2.

Sea Cock Valve ** is used in a ship installation for

safety reasons to close the feed water line during

repair, maintenance, and disuse of the system.

3.

Sea Strainer has a clear bowl with bronze body

filter housing containing a cleanable monel

filter screen. The Sea Strainer filters out large

particulate matter and suspended particles that

would otherwise damage the Booster Pump and

prematurely foul the cartridge Prefilter Element.

4.

Booster Pump supplies a positive pressure to the

Pre-filters and onward to the High Pressure Pump.

The Booster Pump has a performance curve of 85

Ft Head 35 PSI (2.41 BAR) @ 60 Hz with a feed

water flow of 4.5 GPM (17 LPM).

The resulting pressure at the High Pressure Pump

depends on the final installation configuration and

condition of Prefiltration elements.

5.

Low Pressure Transducer #1 Booster Pump Outlet/

1st Prefilter Inlet for line pressure pick up from the

outlet of the Booster Pump to the 1st Prefiltration

component.

6.

Plankton Filter *** This optional filter assembly

contains a cleanable ultra fine monel mesh screen.

The mesh screen removes suspended solids

or biological growth such as plankton. It also

provides longer life to the Pre-filter Elements and

in turn provides lower system maintenance costs.

The Plankton Filter is available as a single housing

or dual housing.

7.

Multi Media Filter *** This optional filter assembly

contains a back-washable bed of sand and

gravel. The sand traps suspended solids larger

than 30 micron which provides longer life to the

pleated cartridge prefilter elements minimizing

maintenance intervals, maintenance labor, and

filter element cost.

WARNING - PREFILTER ELEMENT

: Do

not use third party prefilter elements, use

only Sea Recovery prefilter elements.

Third party prefilter elements do not

properly fit and the seams fall apart. They

also allow by-pass resulting in extensive

and very costly damage to the High

Pressure Pump as well as premature

fouling of the R.O. Membrane Element(s).

8.

Commercial Prefilter takes the place of the Dual

Prefilter. The 5 micron Commercial Prefilter

cartridge element contains 37.5 sq. ft. (3.5 square

meters) of filtering surface area. This oversize

cartridge gives much longer filter element life

greatly extending the time interval between

required maintenance and reduces maintenance

labor and prefilter element replacement cost.

CAUTION - PREFILTER ELEMENT

:

Do not use “string wound” or “fiber”

prefilter elements. String wound and

fiber filter elements are designed for the

Photographic Film Developing Industry.

When used in sea water, they will plug

up rapidly in 1/10th or less the time of a

Sea Recovery supplied prefilter cartridge

element. This will cause frequent shut

downs of the system and very frequent

changing which will result in very high

cost of maintenance, and user frustration.

9.

Dual Pre-Filter removes suspended solids in two

stages. The feed water passes first through a 20

micron cartridge then a 5 micron cartridge. By

stepping the filtration, both prefilter elements gain

longer life and require less maintenance labor and

prefilter element replacement cost.

10. T-Connector Pressure Differential Pick-up *** is

included with Pressure Differential Transducer

#4 for line differential pressure pick up between

optional prefiltration components to the Low

Summary of Contents for Aqua Whisper DX 1400-2

Page 2: ......

Page 3: ...Aqua Whisper DX Modular 450 1800 Owner s Manual...

Page 4: ......

Page 11: ...Introduction Aqua Whisper DX Modular 450 1800 Section 1 INTRODUCTION...

Page 12: ...Introduction...

Page 15: ...Description Aqua Whisper DX Modular 450 1800 Section 2 SYSTEM DESCRIPTION...

Page 16: ...Description...

Page 21: ...Aqua Whisper DX Modular 450 1800 Page 2 5 Description COMPLIANCE CERTIFICATES...

Page 23: ...Aqua Whisper DX Modular 450 1800 Page 2 7 Description...

Page 25: ...Aqua Whisper DX Modular 450 1800 Page 2 9 Description...

Page 30: ...Aqua Whisper DX Modular 450 1800 Page 2 14 Description OPTIONAL ACCESSORIES...

Page 38: ...Aqua Whisper DX Modular 450 1800 Page 2 22 Description This page is intentionally left blank...

Page 39: ...Aqua Whisper DX Compact 450 1800 Section 3 PRE INSTALLATION NOTES Pre installation...

Page 40: ...Pre installation...

Page 56: ...Aqua Whisper DX Modular 450 1800 Page 3 16 Pre installation...

Page 57: ...Aqua Whisper DX Modular 450 1800 Page 3 17 Pre installation...

Page 65: ...Aqua Matic Compact 450 1800 Section 4 ELECTRICAL INFORMATION Electrical...

Page 66: ...Electrical...

Page 75: ...Aqua Whisper DX Modular 450 1800 Page 4 9 Electrical Electrical Motor Wiring Three Phase...

Page 80: ...Electrical...

Page 81: ...Installation Aqua Whisper DX Modular 450 1800 Section 5 INSTALLATION REQUIREMENTS...

Page 82: ...Installation...

Page 94: ...Aqua Whisper DX Modular 450 1800 Page 5 12 Installation...

Page 95: ...Commissioning Aqua Whisper DX Modular 450 1800 Section 6 COMMISSIONING...

Page 96: ...Commissioning...

Page 106: ...Aqua Whisper DX Modular 450 1800 Page 6 10 Commissioning...

Page 107: ...Operation Aqua Whisper DX Modular 450 1800 Section 7 OPERATION...

Page 108: ...Operation...

Page 120: ...Aqua Whisper DX Modular 450 1800 Page 7 12 Operation...

Page 122: ...Aqua Whisper DX Modular 450 1800 Page 7 14 Operation...

Page 123: ...Aqua Whisper DX Compact 450 1800 Section 8 MAINTENANCE AND REPAIR Maintenance...

Page 124: ...Maintenance...

Page 145: ...Troubelshooting Troubelshooting Aqua Whisper DX Modular 450 1800 Section 9 TROUBLESHOOTING...

Page 146: ...Troubelshooting...

Page 167: ...Parts View Aqua Whisper DX Modular 450 1800 Section 10 EXPLODED PARTS VIEW...

Page 168: ...Parts View...

Page 183: ...Aqua Whisper DX Modular 450 1800 Page 10 15 Parts View...

Page 191: ...Aqua Whisper DX Modular 450 1800 Page 10 23 Parts View...

Page 217: ...Sheet 11 3 Aqua Whisper DX Electrical Wiring Diagram 110 120 VAC 50 60 HZ Single Phase...

Page 219: ...Sheet 11 5 Aqua Whisper DX Electrical Wiring Diagram 208 240 VAC 50 60 HZ Single Phase...

Page 221: ...Sheet 11 7 Aqua Whisper DX Electrical Wiring Diagram 200 240 VAC 50 60 HZ Three Phase...

Page 223: ...Sheet 11 9 Aqua Whisper DX Electrical Wiring Diagram 380 460 VAC 50 60 HZ Three Phase...

Page 225: ......