NDE754

March 2000

Page 19

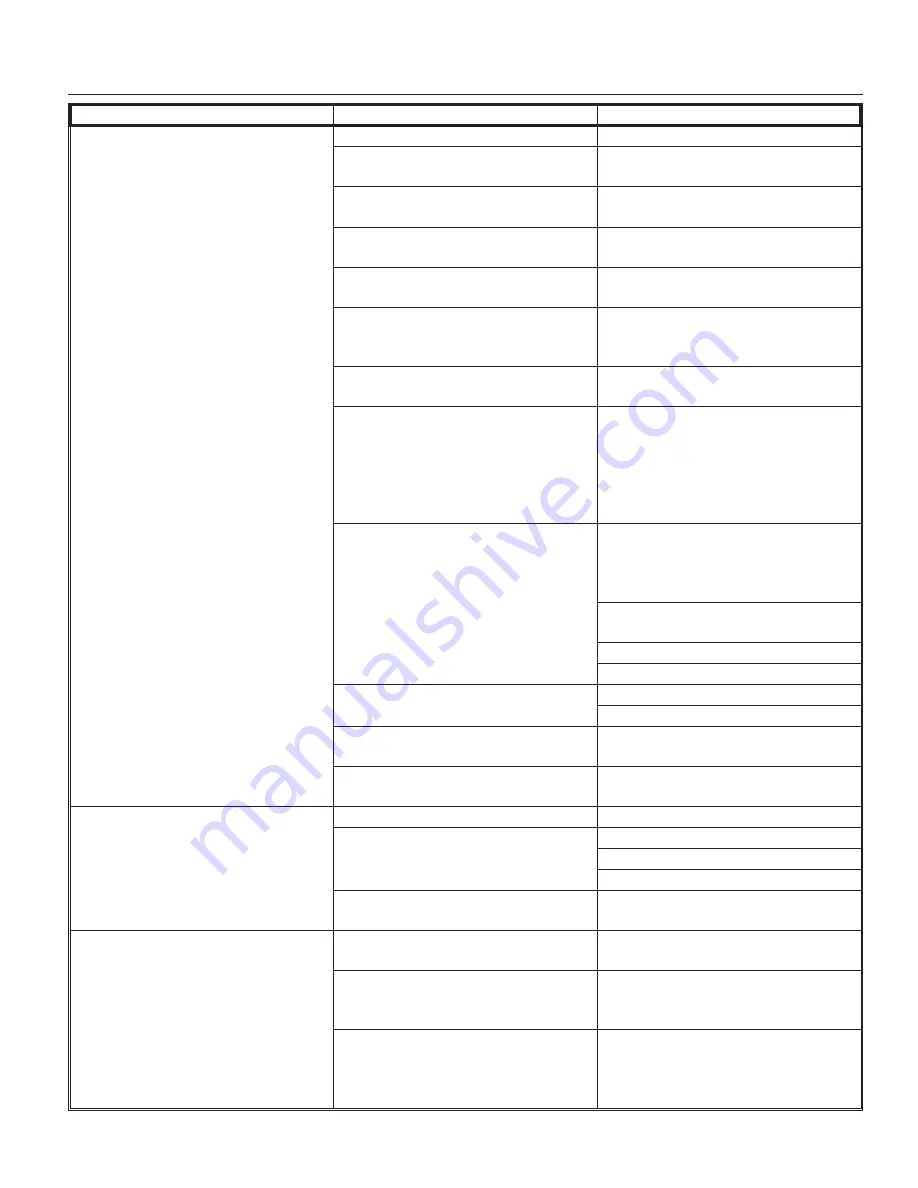

SERVICE DIAGNOSIS

Symptom

Possible Cause

Probable Correction

No ice is made, nothing operates Unit off due to no power

Restore Power

Unit off due to master switch in

OFF position.

Switch master switch to ON.

Unit off due to low water level.

Check water supply, filter, strainer,

float valve. Correct water supply.

Unit off due to ice level sensors

(photo-electric eyes) blocked.

Check/clean ice level sensors.

Unit off due to scale on water level

sensor.

Clean water level sensor.

Unit off due to high pressure

control open.

Check for water interruption (water

cooled) or fan motor failure (air

cooled).

Auger motor hums but does not

turn.

Auger can’t turn. Circuit board has

not yet shut unit down.

Unit is shut down

Circuit board has shut ice machine

down due to high auger motor amp

draw. Check for cause of high amp

draw, including bearings,

gearmotor condition and scale on

auger and in evaporator.

Low pressure control open

Auger not turning due to: motor

failure; auger relay failure on circuit

board; or gears stripped. Check

drive train.

TXV restricted or not metering.

Check bulb temperature.

Lack of refrigerant. Check for leak.

Check for a restricted system

No power to circuit board.

Check harness

HI or low pressure cut out open

Circuit Board gear motor relay will

not close

Check, replace board

Water level or ice level sensor

failed.

Check, replace sensor

No ice, auger motor is turning

Compressor contactor coil is open Check/replace contactor

Compressor will not start

Check start capacitor.

Check start relay

Check compressor windings

Circuit board compressor relay will

not close.

Check, replace board

Unit makes ice, but very slowly.

High discharge pressure because

of a dirty condenser

Clean the air filter and condenser.

Low capacity because the auger

and evaporator are coated with

mineral scale

Clean the water system

Low suction pressure due to low

refrigerant charge

Locate leak. Recover refrigerant,

repair leak, replace dryer,

evacuate and weigh in the

nameplate charge