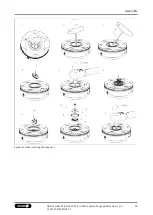

Assembly

4.3.4 NSE3 138-V1, NSE3 138-V1-K, NSE3 138-V4, NSE3 138-V4-K

Fastening in the installation space with 5 M8 screws and a fitting

screw M8.

The assembly module can be positioned by means of two

centering diameters of the installation space:

Ø 110 H6

in the lower range. For partial and full installation.

Ø 138 H6

in the upper range.

The exact position orientation is done with a fitting screw with a

diameter of Ø 9 f7 x 5 mm. Precise alignment and positioning of

the quick-change pallet system requires that the fitting bore Ø 9

H7 on the opposite side is precisely positioned in the mounting

position.

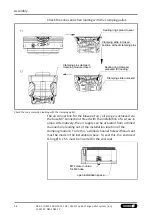

The air connection is normally made via the bottom coupling holes

in the floor of the unit.

Hose-free direct

connection

(seal Ø 9 x 1.5)

Installation type:

full installation

Detaching

thread M10 x 10

Slot for

position

orientation

and torque

transmission

Unlocking

connection ← →

Turbo connection → ←

Alternative air bleeding

method (M4 x 4 set-screw)

Installation situation:

partial installation

G1/8" air connection via

fitting

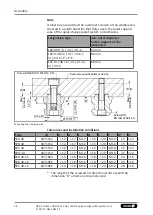

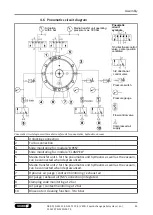

* All clamping systems of equal height within 0.02 mm

** Measure of clearance for fitting screw

*** Measure of clearance for IXB V1

M4 mounting thread

for monitoring system

AFS

M5 thread

Fitting screw for

positional

orientation

Ø 20

Fixing hole for fitting

screw

Fitting screw

Fitting screw

29

08.00 | NSE3 138, NSE-T3 138 | VERO-S quick-change pallet system | en |

1152197 -NSE3 NSE-T3