Maintenance and Care

7 Maintenance and Care

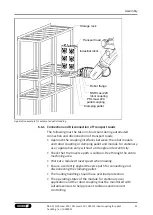

The quick-change pallet system is designed for low-maintenance

operation, so that opening and disassembling the clamping

modules is only necessary in exceptional cases.

CAUTION

Risk of injury and risk of damage to the clamping module when

opening the housing cover.

If the clamping module has to be disassembled, ship the module

to SCHUNK for repair.

The cover of the clamping module is spring preloaded and must

only be removed by trained specialist personnel.

NOTE:

Detaching threads facilitate the removal of the modules

from the modules for stationary use / application Link Befestigung

und Anschluss.

To ensure the quick-change pallet system operates perfectly, the

following instructions are to be observed:

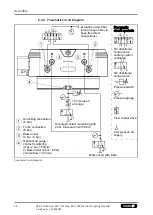

Pressure medium:Compressed air, compressed air quality

according to ISO 8573-1:7 4 4

The air supply must be supplied via a separate maintenance unit.

The robot coupling is ready for use with non-lubricated

compressed air.

• Make sure that the contact surfaces of the interface are always

clean.

• Make absolutely sure that no chips of any kind can enter the

interface and that the interface does not fill with cooling

emulsion, which is particularly possible with vertical positioning

of the clamping pin axis. If the interface should fill with cooling

emulsion, initiate the unlocking process and dry out the

interface in actuated state.

• Only use high-quality cooling emulsion with anti-corrosive

additives during processing.

• Check the units at regular intervals (at least every two weeks or

after 1000 clampings). The system is functioning correctly if the

clamping slides move smoothly at minimum system pressure

(5 bar).

• Regularly check all electronic components such as the inductive

proximity switch and the installed inductive stroke measuring

system for damage and functional reliability. Damaged or

susceptible electronic components must be replaced as a

precaution.

33

09.00 | NSR maxi 220 / PKL maxi 220 | VERO-S robot coupling for pallet

handling | en | 0489051