Assembly

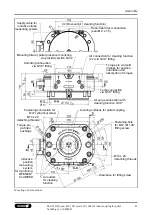

6.4 Coupling Interface

The NSR maxi 220 robot coupling has two different alignment aids

for the PKL pallet coupling.

The mounting interface for the clamping pallet is identical for both

versions of the pallet couplings.

Torque pin version I

Here, the pallet coupling is aligned with the robot module using

the slanted contact surfaces. The wedge slants on the pallet

coupling center precisely with the machining contour of the robot

module during assembly.

Note:

The PKL maxi 220 pallet coupling can only be coupled using

torque pin version I.

Torque pin version II

The pallet coupling engages in the fitted bushings of the robot

module using alignment pins during joining.

Control function

for presence of pallet

coupling via inductive

proximity switch NI 32

Torque pin variant I

Pallet coupling

PKL maxi 220

ID No. 0471950

Clamping pallet

Air ducts for

cleaning function

Torque pin variant I

Position orientation and

torque support through

self-centering mold inclines

Air connections for cleaning function

via G1/8" screw connection

(control also possible on base side)

Torque pin variant II

Torque pin variant II Position

orientation and torque support

through alignment pins

and fitted bushings

Sunk 1 mm deep

Torque pin version I and version II

25

09.00 | NSR maxi 220 / PKL maxi 220 | VERO-S robot coupling for pallet

handling | en | 0489051