5

SLG 420

Operating instructions

Safety light grid

EN

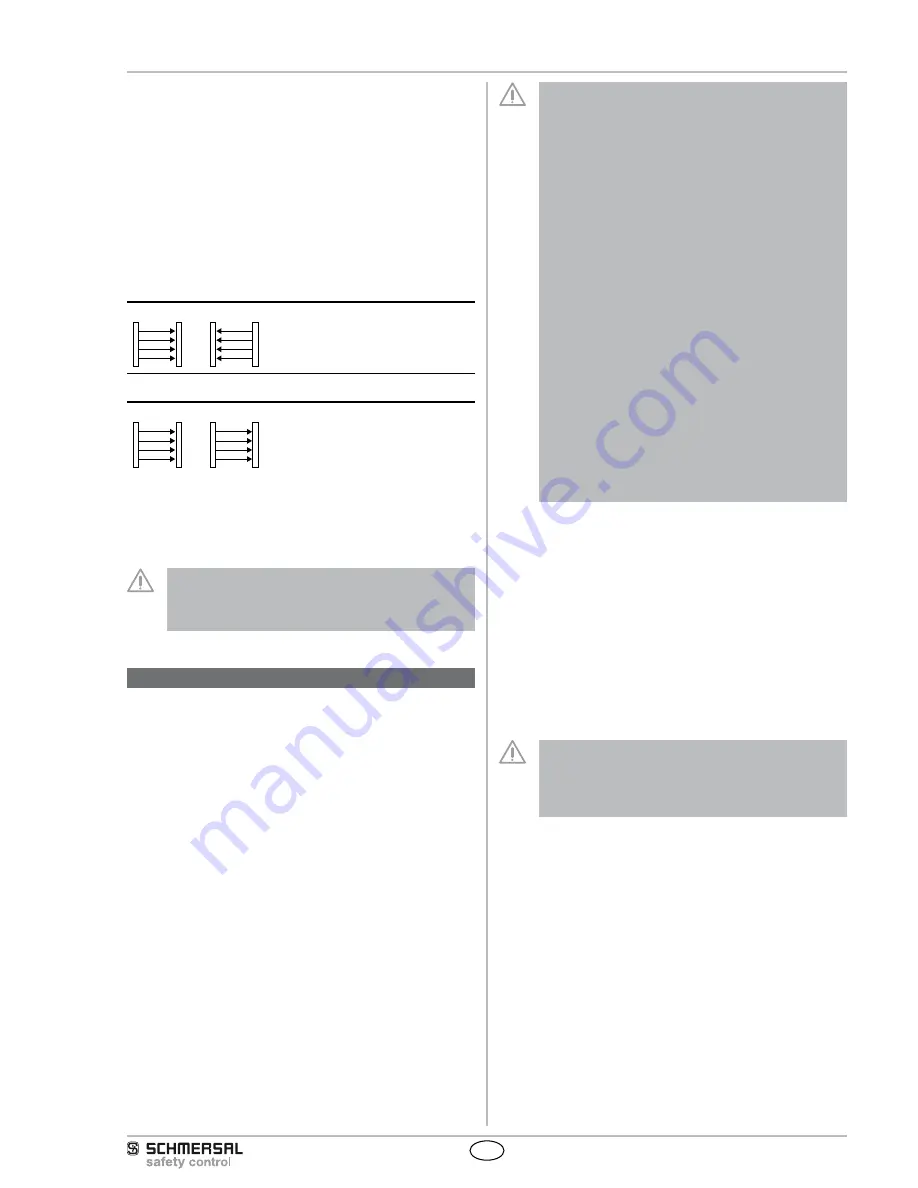

2.10 Beam coding

The beam coding of the safety light grid must be adjusted, when

systems operating in each other's vicinity and a set-up as shown in the

image below (no interference) is impossible.When supplied, the beam

coding is not active. With beam coding A, a receiver can distinguish the

beams of the transmitter with the same beam coding, which are desti-

ned to this particular receiver, from foreign beams. The beam coding A

must be set for each sensor (receiver and transmitter) individually. The

function is activated by means of the NSR-0801 BUS converter and a

PC or laptop.

If adjacent systems are operated without beam coding, the user is at

risk.

no interference

E

E

R

R

Interference: beam coding required!

E

R

R

E

• The beam coding increases the safety and avoids mutual interference

of adjacent systems.

• The beam coding increases the immunity against optical interference

(e.g. sun light, welding sparks).

• The beam coding A is permanently shown by the transmitter and the

receiver by means of flashing LED's (refer to LED status information).

The response time of the system is increased when beam

coding A is used. To this end, the safety distance must be

adjusted to the hazardous movement. Refer to chapter

Response time.

3. Mounting

3.1 General conditions

The following guidelines are provided as a preventative warning notice

to ensure safe and appropriate handling. These guidelines are an

essential part of the safety instructions and therefore must always be

observed and respected.

• The SLG 420 must not be used on machines, which can be

stopped electrically in case of emergency.

• The safety distance between the SLG 420 and a hazar-

dous machine movement must always be observed and

respected.

• Additional mechanical safety guards must be installed so

that the operator has to pass by the protection field to reach

the hazardous machine parts.

• The SLG 420 must be installed so that the personnel always

must be outside of the hazardous area when operating the

machine.

• An incorrect installation can lead to serious injuries. An

incorrect installation can lead to non-detected areas.

• Never connect the outputs to +24VDC. If the outputs are

wired to +24VDC, they are in ON state, as a result of which

they are unable to stop a hazardous situation occuring on

the application/machine.

• The safety inspections must be conducted regularly. The

SLG 420 must not be exposed to inflammable or explosive

gasses.

• The connecting cables must be connected in accordance

with the installation instructions. The fixing screws of the

end caps and the mounting angle must be firmly tightened.

• Additional measures could be required to ensure that the

electro-sensitive device does not present a dangerous

breakdown, when other forms of light beams are available in

a special application (e.g. use of wireless control devices on

cranes, radiation of welding sparks or effects of strobosco-

pic lights).

3.2 Protection field and approach

The protection field of the SLG 420 consists only of the available

individual beams with a distance of 300, 400 or 500 mm. Additional

protective devices must ensure that hazardous machine movements

can only be reached after passing through the protection field.

The SLG 420 must be installed to so that the hazardous area is com-

pletely protected, if necessary by means of additional safety guards.

The safety distance before the hazardous point to the SLG safety

guard must be imperatively respected. The safety distance enables the

presence of persons within the hazardous area. Therefore, it must be

ensured that the hazardous movement can only take place, when no

persons are inside the hazardous area anymore.

The legal and governmental provisions must be observed for the

operation and use. These provisions are usually region- and country-

dependent.

The command devices (enabling button) must be installed

outside of the hazardous area sot hat any operation from

within the hazardous area is prevented. The operator must

have a clear view on the hazardous area, when actuating the

command device (enabling button).

3.3 Alignment

Procedure:

1. The transmitter and the receiver must be fitted parallel to each other

and at the same height.

2. Turn the transmitter and monitor the diagnostic window of the recei-

ver. Fix the light grid, when the LED OSSD ON (green) is on and the

LED signal reception (orange) is off.

3. Determine the max. rotating angle to the left and to the right, at which

the LED OSSD ON (green) is on and tighten the mounting screws in

central position. Make sure that the LED signal reception (orange) is

not on or flashing.