3

BNS 260 AS

Operating instructions

Safety sensor

EN

3. Mounting

3.1 General mounting instructions

Please observe the remarks of the standards ISO 12100,

ISO 14119 and ISO 14120.

• Fitting is only authorised in a de-energised condition

• Do not use the sensor and the actuator as a mechanical backstop.

• Any mounting position, provided that the active surfaces are opposite

• Do not subject the safety sensor and actuator to extreme vibrations

and shocks.

To avoid any interference inherent to this kind of system and any

reduction of the switching distances, please observe the following

guidelines:

• Ensure the safety sensor is mounted on a flat surface

• Do not install the safety sensor and the actuator in strong magnetic

fields

• If possible, do not mount the sensor and the actuator on ferromagnetic

material. A non-magnetic spacer of at least 5 mm thick or the original

spacer must be used. The use of non-magnetic fixing screws is

recommended also.

• Keep away from metal chips

• The mounting distance between two sensors should always be at

least 50 mm

The actuator must be permanently fitted to the safety guards

and protected against displacement by suitable measures

(tamperproof screws, gluing, drilling of the screw heads).

3.2 Dimensions

All measurements in mm.

Sensor with cable, for left hinged door

26

6

2000

13

36

4

19

22

¤ 4,5

LED

BPS 260-1/-2 actuator

6

13

36

26

4,5

4

19

22

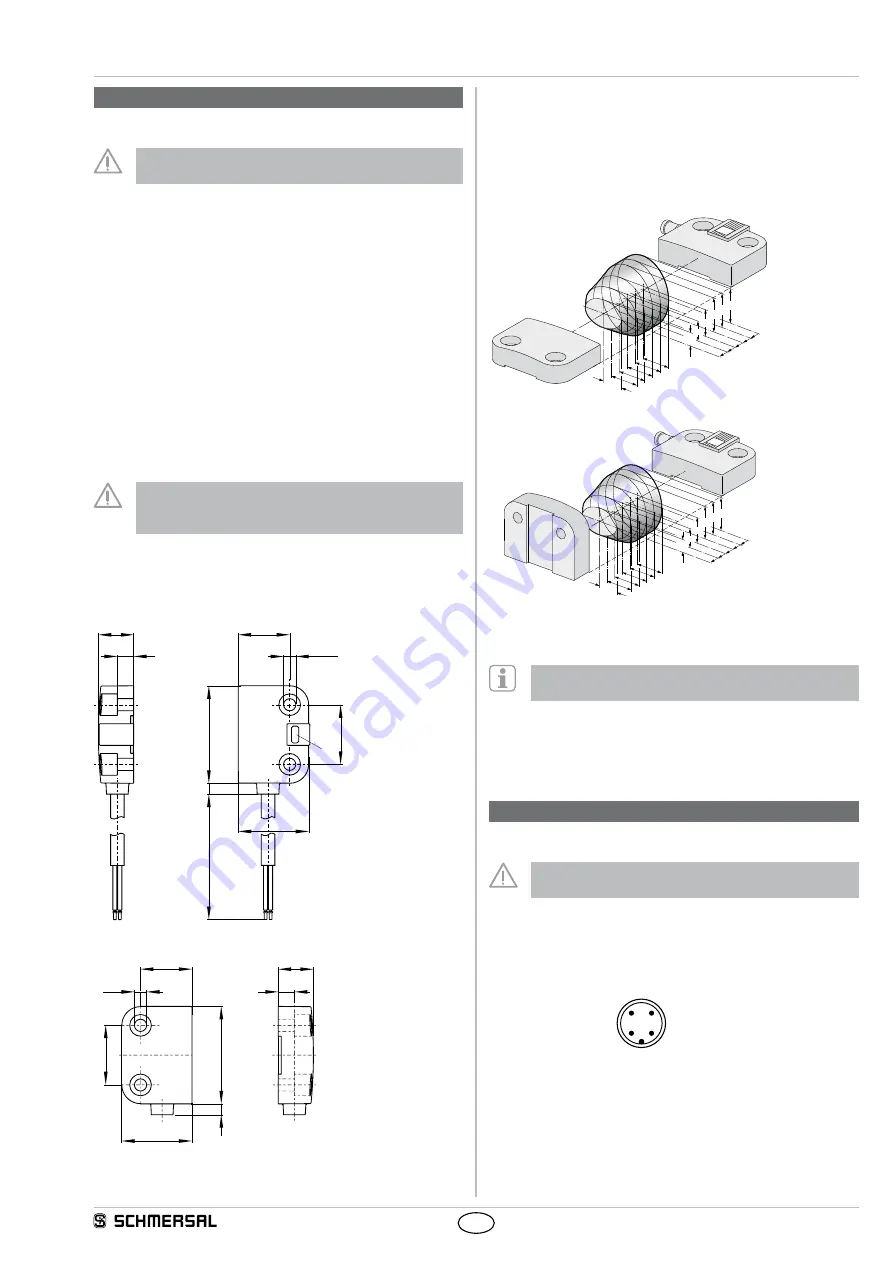

3.3 Axial misalignment

A horizontal and vertical misalignment of the safety sensor and the

actuator is tolerated. The possible misalignment depends on the

distance of the active surface of the sensor and the actuator. The

sensor remains active within the tolerance range.

The specified switching distances refer to opposedly mounted safety

sensors and actuators.

3,5

3,5

3,5

3,5

3,5

3

3

4

5

2 1

0

5

5

5

4

3

2

BPS 260-1

3,5

3,5

3,5

3,5

3,5

3

3

4

5

2 1

0

5

5

5

4

3

2

BPS 260-2

Assured switching distance: s

ao

= 5 mm

assured switch-off distance: sar = 15 mm

Recommended Adjustment

Align the safety sensor and actuator at a distance of 0.5 x s

ao

.

3.4 Adjustment

Adjust the safety sensor and the actuator to the safety guard. The

correct functionality of both safety channels must be checked by means

of the connected safety-monitoring module.

4. Electrical connection

4.1 General information for electrical connection

The electrical connection may only be carried out by

authorised personnel in a de-energised condition.

Connection to the AS interface system is realised through the vacant

cable end or an M12 connector. The M12 connector is A-coded.

The wiring configuration of the M12 connector is defined as follows (to

EN 62026-2):

spare

3

2

1

4

AS-Interface - (blue)

AS-Int (brown)

spare