24 | GB

www.scheppach.com

+(49)-08223-4002-99

+(49)-08223-4002-58

www.scheppach.com

+(49)-08223-4002-99

+(49)-08223-4002-58

Residual risks and accident prevention stand-

ards

Neglect of ergonomic principles

Negligent handling of personal protective equip-

ment (PPE)

Negligent handling or ommission of the personal pro

-

tective equipment may cause serious injuries.

-

Wear prescribed personal protection equipment.

Human behaviour, misbehaviour

-

For any work be fully concentrated.

m

Residual risks

- Cannot be entirely excluded.

Danger from noise

hearing damage

Prelonged unprotected work with the device may

cause hearing damage.

-

Always wear ear-muffs.

In case of emergency

In case of a possibly occuring accident take the nec

-

essary first aid steps as appropriate and obtain quali

-

fied medical aid as quickly as possible.

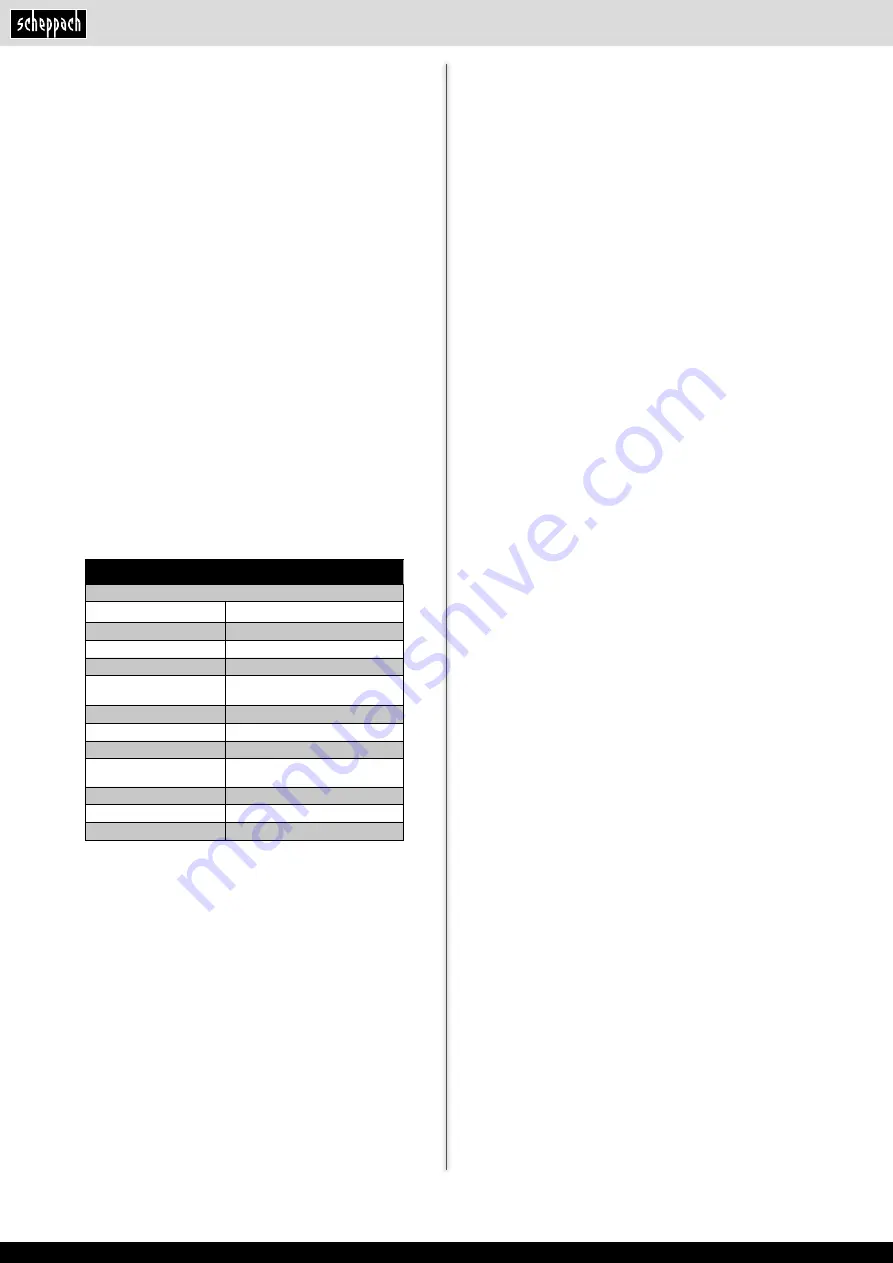

6. Technical data

MS196-51

Technical data

Type engine

four stroke engine/air cooled

Cubic capacity

196 cm³

Rotation speed

2800 U/min

Max. engine output kW

4,4 kW /

6,0 HP

Fuel

Normalbenzin/Bleifrei max.

5% Bioethanol

Capacity tank

0,8 l

Motor oil

SAE 30 / 10W30

Capacity tank/oil

0,6 l

Cutting height

adjustment

25-75 mm / 7 -stages

Collection bag capacity

60 l

Cutting width

51 cm

Weight

35,0 kg

Subject to technical changes!

Information concerning noise emission measured ac-

cording to relevant standards:

Sound pressure L

pA

= 83,2 dB(A)

Uncertainty K

PA

= 2,5 dB(A)

Sound power L

WA

= 95,9 dB(A)

Uncertainty K

PA

= 0,61 dB(A)

Wear ear-muffs.

The impact of noise can cause damage to hearing.

Vibration A

hv

(left/right) = 6,36 m/s

2

Uncertainty K

PA

= 1,5 m/s

2

Reduce noise generation and vibration to a minimum!

•

Use only equipment that is in perfect condition.

•

Maintain and clean the equipment regularly.

•

Adopt your way of working to the equipment.

•

Do not overload the equipment.

•

Have the equipment checked if necessary.

•

Switch off the equipment when not in use.

• Wear gloves.

When using the petrol lawn mower for extended peri

-

ods, vibration-induced circulatory problems may oc

-

cur (white finger disease).

We cannot give exact details about the duration of

use in this case because it is different for each indi

-

vidual.

The following factors can influence the condition:

•

Circulatory problems in the user’s hands

•

Low outside temperatures

•

Extended periods of use

We therefore recommend you wear warm work gloves

and take regular breaks.

7. Before first use

Assembling the components

Some parts of the mower come disassembled. For

quick and easy assembly, read and follow the instruc

-

tions below.

Important!

You will need the following additional tools (not sup

-

plied) for assembly, and also for maintenance work:

•

A 1 liter measuring jug (oil/petrol resistant)

•

A petrol can (5 liters is sufficient for approx. 6 op

-

erating hours)

•

A funnel (suitable for the tankʼs petrol filler neck)

•

Household wipes (to wipe up oil/petrol residue; dis

-

pose of these at a filling station)

•

A petrol suction pump (plastic, available from DIY

stores)

•

An oil can with hand pump (available from DIY

stores)

•

0,6 liter of engine oil (SAE 30)

Assembly

1.

Take the mower and attachment parts out of the

packaging and check that all parts are present.

2.

Attach the lower push bar to both sides of the

mower with two screws (a, e), 2 washer (b), 2

hexagon nut (c) (d) each. Make sure that the ca

-

bles, which will be attached later, are not in the

way (Fig. 2-3).

3.

Attach the upper push bar on the lower push bar

with one quick-release lever (5), one fixation slice

(g), one washer (b) and one plastic nut (f) each on

both sides (Fig. 4-5). Note the correct alignment

of the quick-release lever fixation slice ensuring

the quick-release function remains intact.

4.

Insert the pull start handle (17) in the designated

hook as shown in Fig. 6.