www.scheppach.com /

+(49)-08223-4002-99 /

+(49)-08223-4002-58

GB

| 47

Adjusting the idling speed (Fig. 25)

If the saw chain continues to idle, you must correct

the idle speed.

1. Remove the plug (T).

2. Let the engine warm up for 3-5 minutes (no high

speeds!).

3. Turn the adjusting screw (R) using a flat-head

screwdriver:

clockwise

- Idle speed increases (+)

counterclockwise

- Idle speed decreases (-)

Idling speed max.: 3500 min

-1

Contact the manufacturer if the saw chain continues

to idle.

Attention!

Do not work on the chain saw!

Important:

No adjustments can be made to the plug

L / H.

Carburetor setting

The carburetor has been set to its perfect adjustment

at the factory. If it requires adjusting, take the saw

to your nearest authorized after-sales service outlet.

m

WARNING!:

You may not make settings on the

carburetor itself!

Bar

•

Check after every 8 hours of work to ensure uni-

form wear.

Saw chain

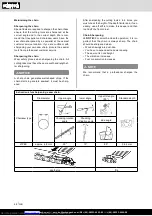

Saw chain Tension

Periodically check the chain tension and adjust if

necessary, so that after use the chain is snug against

the rail, but still loose enough that it can be pulled by

hand. (Fig.8)

Breaking in a new saw chain

A new chain and bar will need chain readjustment af-

ter as few as 5 cuts. This is normal during the breakin

period, and the interval between future adjustments

will begin to lengthen quickly.

Chain lubrication

Always make sure the automatic oiler system is

working properly. Keep the oil tank filled with Chain,

Bar and Sprocket Oil.

Adequate lubrication of the bar and chain during cut-

ting operations is essential to minimize friction with

the guide bar.

Never starve the bar and chain of lubricating oil. Run-

ning the saw dry or with too little oil will decrease cut-

ting efficiency, shorten saw chain life, cause rapid

dulling of chain, and lead to excessive wear of bar

from overheating. Too little oil is evidenced by smoke

or bar discoloration.

•

Dust and dirt between the fins on the cylinder may

cause the machine to overheat.

Other maintenance points before each use

•

Check for leakage from oil or fuel tanks.

•

Check the unit for loose parts and screws. Specif-

ically, the chain, the bar and the hand grips.

•

If you find defects on the machine, fix them im-

mediately.

Oil-/Fuel filter (Fig.21)

m

CAUTION!:

Never operate the saw without the

Oil-/fuel filter (L1/L2). After every 100 hours of op-

eration the Oil-/fuel filter needs to be cleaned or re-

placed when damaged. Drain the Oil-/fuel tank com-

pletely before replacing the Oil-/filter.

•

Remove the Oil-/fuel tank cap (12/14).

•

Make a handle from soft wire.

•

Insert it into the opening of the Oil-/fuel tank and

hook the Oil-/fuel hose. Pull the Oil-/fuel hose

carefully to the opening until you can grab it with

your fingers.

m

NOTE

Pull the hose so it is not quite out of the tank.

•

Lift the Oil-/fuel filter (L1/L2) from the tank.

•

Remove the Oil-/fuel filter with a twisting motion

and clean it. If it is damaged, discard the Oil-/fu-

el filter.

•

Insert the cleaned Oil-/fuel filter or a new one. Plug

one end of the Oil-/fuel filter into the tank opening.

•

Make sure the Oil-/fuel filter is seated in the lower

tank cap. Move the Oil-/fuel filter with a long screw-

driver to put it in its proper slot.

•

Fill the Oil-/fuel tank with fresh saw chain oil or fu-

el mixture. Put the Oil-/fuel tank cap on the tank.

Spark plug (Fig.17-19,22)

m

NOTE!:

In order for the saw motor to remain pow-

erful, the spark plug (G) must be clean and properly

gapped (0.6-0.7 mm). Spark plugs should be cleaned

or replaced every 20 hours.

•

Set the power switch (11) to „Stop“.

•

Remove the air filter cover (5) by removing the air

filter mounting nut (6). The cover can then be re-

moved.

•

Disconnect the spark plug from the ignition wire

by gently pulling it and turning the spark plug (G).

•

Remove the spark plug with a spark plug wrench

(20). Do not use other tools.

•

Clean the spark plug with a copper wire brush or

replace it with a new one. (Fig.22)

Heruntergeladen von

Handbücher-Suchmachiene