15

The message must be acknowledged pushing STOP.

This messages means that an hydraulic block of the machine occurred, and then the pumps has

been switched off as safety procedure. In this case is suggested to perform a reset procedure and

investigate on the possible hydraulic origins of the problem.

If the origin of the problem is just a malfunctioning of the signal pressure switch, it is possible to

start again the unit, activating the bypass.

BYPASS WARNING

This message advice or remember that the unit is working in bypass mode (then some safety

functions are disabled).

CHANGE PUMP FILTERS

This is a blinking messages that must be acknowledged pressing the key STOP

This messages suggest to replace the filter of the pump group.

3. Operation

3.2. First start-up procedure

The first start-up procedure is necessary to start the first time a new system, just installed.

The purpose of the procedure is basically purge out the air from the system.

It can be used as well after a filter replacement, or after other maintenance operations.

Preliminary checks:

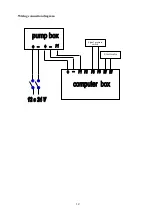

Verify that all components are connected correctly.

Verify that the filters cartridges are installed.

Verify that the seawater valve, and the possible drain valve, are opened.

Verify that the reset valve is closed (lever orthogonal to the body valve) and the positioner

completely unscrewed.

Verify that the small gray valve on the active carbon filter is opened and the fresh water

pump of the boat is on.

Verify that the fresh water tanks are full enough (at least 50 liters) to perform the first

washing operations.

Start-up procedure:

1.

Open halfway the depressurization valve (45°).

2.

Activate the start up procedure throw the function of the MENU (select the specific function

in the menu mode, exit from menu mode pushing STOP, and start the procedure pushing

START).

3.

Close the depressurization valve when the display shows the specific message.

The procedure lasts about 3 minutes. It can anyway stopped anytime pushing STOP.

After the procedure the system is ready to start normally.